Introduction to SLS 3D printing

SLS is an advanced additive manufacturing technique that enables innovators to precisely and effectively obtain their most audacious ideas.

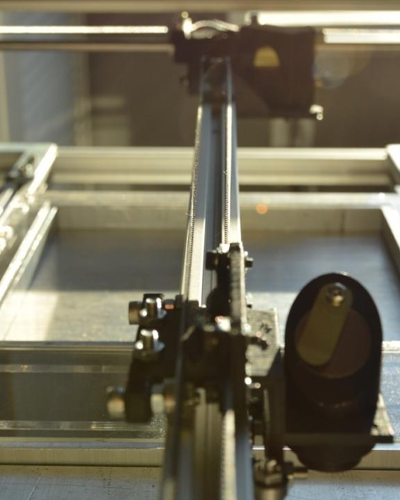

High-powered lasers are used in selective laser sintering (SLS) to bond finely powdered material into a solid structure. Using this method, a printer deposits a uniform layer of powder and then precisely sinters it. This procedure is repeated until the part is finished. Using a digitally generated CAD (computer-aided design) file as guidance, a laser is pointed at the powder bed at specified spots in space to construct the desired shape of the product.

High-fidelity products, such as precise, low-volume parts for the automotive and aerospace industries, can be produced by SLS machines. Large or geometrically complicated, detailed, and extremely accurate items of different materials can be made with SLS.

The adaptability of SLS 3D printing is among its most alluring qualities. SLS provides a versatile solution for various applications across industries like consumer products, automotive, aerospace, and medical, from low-volume manufacturing to rapid prototyping. SLS produces excellent outcomes with short lead times, whether you're manufacturing end-use parts or prototyping new product concepts.

With SLS, engineers and designers may more easily iterate and customize their designs, adapt to changing needs, and improve designs without expensive tooling changes.

SLS has benefits that go beyond its capacity to create complex designs. Because leftover powder can be recycled, SLS produces less waste than typical subtractive production methods, making it a more environmentally friendly choice. Furthermore, complicated assemblies can be produced using SLS printing as single, fully-functional components, saving time and material during post-processing.

Achievable Feature Size:

| Feature | SLS |

| Maximum Build Volume | 340 mm x 340 mm x 600 mm |

| Wall thickness | 0.8mm |

| Holes | 0.8-1.0mm |

| Surface Finish | Better than FDM |

| Accuracy | 0.2 |

| Material | PA Nylon |

| Mechanically | Strong and flexible |

Applications

- Functional prototyping

- Short-run

- bridge

- custom manufacturing

Post Processing

Polishing Dyeing and Painting

Pros & Cons

Pros

- Strong functional parts

- Design freedom

- No need for support structures

Cons

- Rough surface finish

- Limited material options