3D printing, also known as “additive manufacturing” and ‘rapid prototyping’ is contemplated to be the “second industrial revolution”, for the orthopedic trauma surgery.

An expeditious arrival of 3D printing technology, surgeons have recently started to apply this in nearly all fields of orthopedic trauma surgery. Computer generated tomography or resonance images of trauma patients can be used for making perceivable 3D constructed models. Patient specific 3D anatomy models can help surgeons enhance their knowledge of patient’s precise

patho-anatomy, regarding both traumatized bones and soft tissue as well as normal areas, and therefore help in accurate preoperative planning.

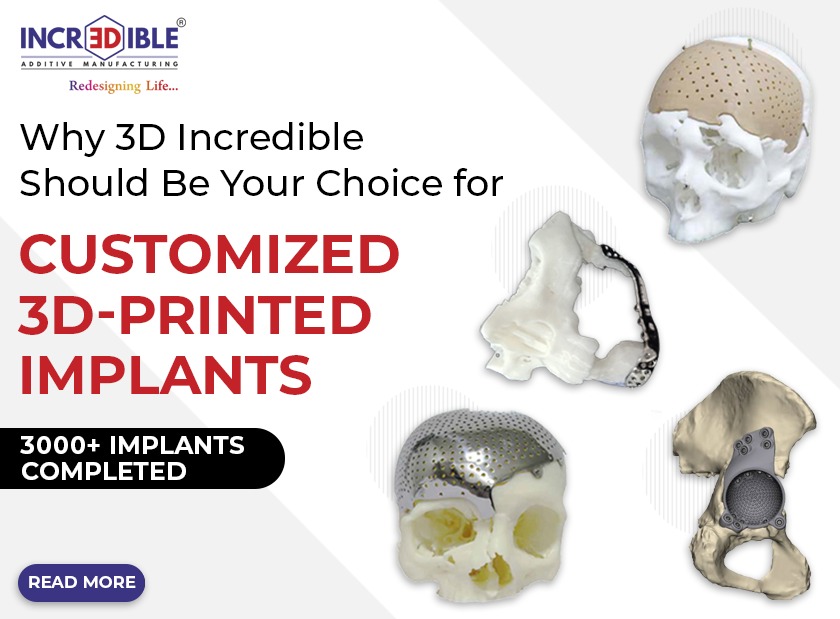

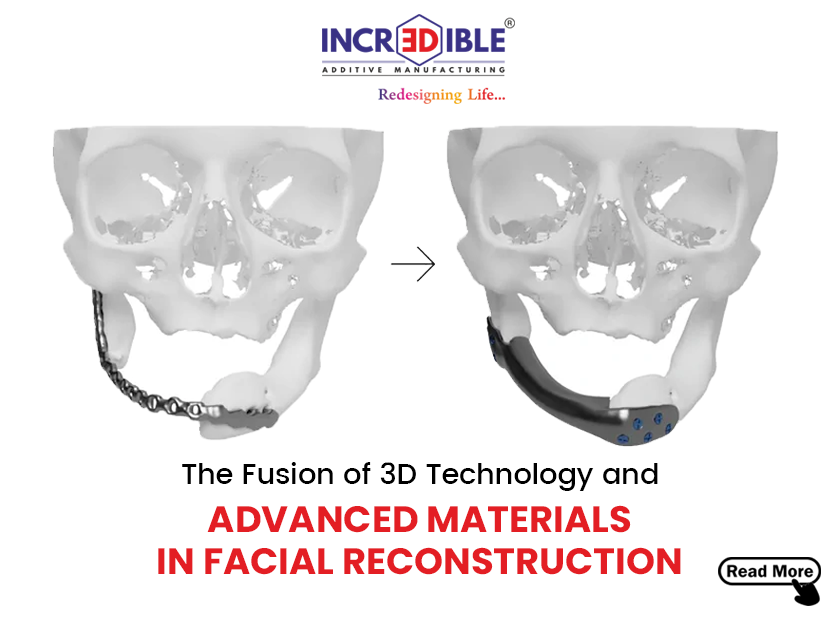

A 3D printed custom instrumentation for a patient can help achieve precise implant placement. This helps in manufacturing a customized implant can be manufactured to match an individual’s anatomy. The role of 3D printing is not limited to the operation theatre as it can also help in the manufacture of better individualized orthosis and prosthetics.

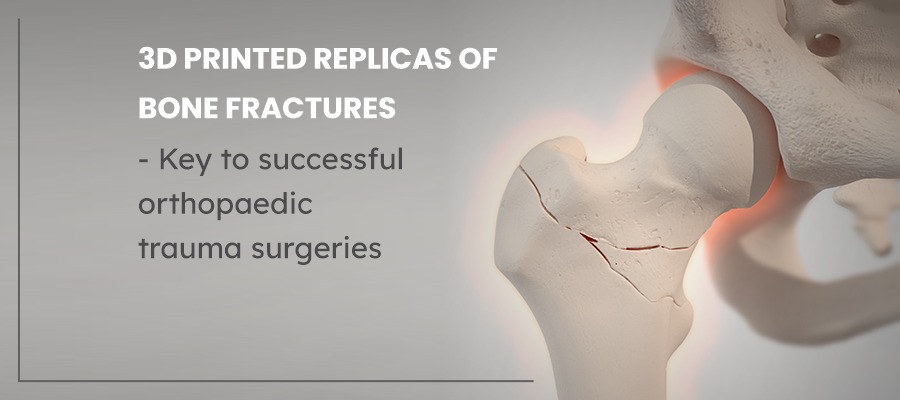

The 3D printed fracture replica helps a doctor find exactly the position of an ongoing fracture before they begin a surgery or open the fractured joint. The point of creating a 3D printed anatomy model is to increase the success rate of the surgery on the first attempt so the patient can heal faster with no chronic pain. The innovation of using 3D printed replicas of bone fractures, bones, organs or other body parts can help doctors, surgeons and researchers thoroughly test methods before the beginning of the surgery.

The products of 3D printing technology were used to analyze complex cases initially, however nowit is becoming common, and is likely to have a significant impact on all of our practices in the coming years, as they offer several benefits.

– 3D printed model can help in the training of new surgeons in complicated surgical areas like pelvic-acetabular trauma.

– The model can be sterilized and reviewed intraoperatively if it’s important.

– Preoperative review of the 3D model allows the surgeon to anticipate intraoperative difficulties, select optimal surgical approach, plan implant placement, visualize screw trajectory etc. and access the need for special equipment.

– It can also help in evaluation for restoration of individual anatomy after surgery.

– In some cases, it can help in making a precise anatomical diagnosis, where it is not otherwise obvious, and in planning subsequent management.

– 3D printing of individualized artificial cartilage scaffolds and 3D bioprinting are some areas of rising interest amongst surgeons.

Conclusion

Across the world, orthopedic surgeons, health care professionals and scientists are enthusiastically using 3D printing technology for designing patient specific models, instrumentation, implants, orthosis and prosthesis, besides 3D bioprinting of bone and cartilage scaffolding, and the same has been applied for nearly all areas of orthopedic trauma surgery, from head to foot.Incredible AM Pvt. Ltd. is a leading manufacturer of 3D printed models for medical requirements that are available in various materials like ABS, PLA, Silicon, Sandstone and Nylon as per surgeon’s requirement.