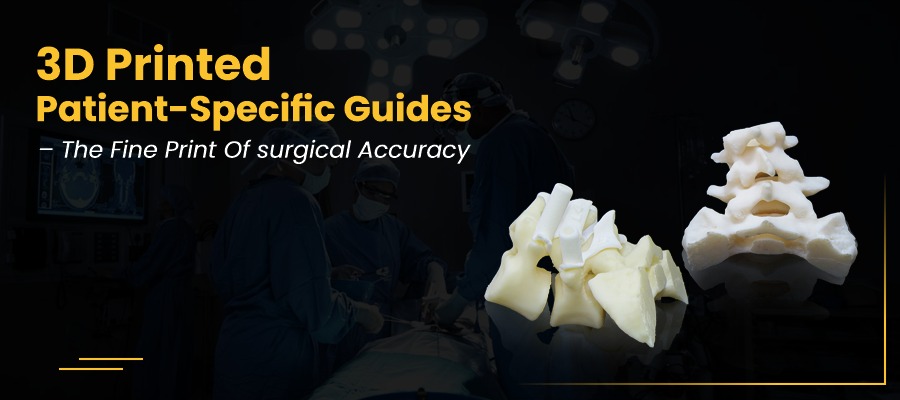

Patient-specific surgical guides are one-time use instruments that are required when precise cutting at a specific position and angle is desiredduring surgery. These guides are created during preoperative planning, in consultation with the surgeon. It is made solely referring to the patient’s unique anatomy and helps the experts to implement the operational plan, successfully.

Additive manufacturing is used to manufacture these patient-specific surgical guides. In recent times, 3D printing has become a burgeoning technology in the medical industry. The PSI surgical guides have shown many positive impacts on the operations and the health of patients. This shift towards the technology of 3D metal printing is because ofits fewer geometrical limitations in complex cases. Even though, being a relatively new technology, it has gained reliability with its accuracy and affordability.

Additive manufacturing has also revolutionized the step of pre-operative or surgical planning. It allows to a better understanding of patient’s anatomy, using few resources, and reduction in the duration of the treatment. The predictability increases the reliability and accuracy of the surgery. In addition, increases the chances of the patient’s quick recovery.

Patient-Specific Surgery Guides

These single-use PSI medical devices that help prevent possible inaccuracies during surgery,it can be widely used forpatient-specific implants as well as standard implants. The PSI surgical guides are mostly used for spinal structures to place pedicle screws precisely. Also, for replacing, knee, hip, and other joints. It allows experts to carry out a highly controlled and accurate operation. Guides are designed as per the patient’s anatomical model using computer-aided tomography images. Other factors influencing its designs is the pathology of the patient and the surgeon’s requirements.

Surgical Guides Made By – Incredible AM Pvt. Ltd,

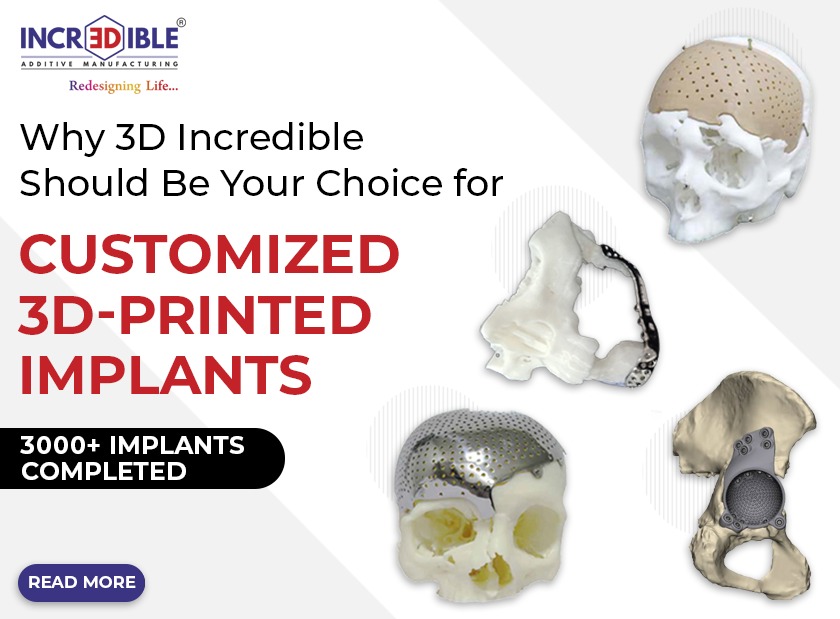

Incredible has a state-of-the-art plant in Pune, Maharashtra and has been catering the requirement in the medical sector for more than 2 years. The lab is equipped with cutting-edge technology to create 3D implants, prototype, and surgical guides.

Their digital workflow includes CT/MRI Scans, Converting the scans into 2D CAD models, designing the implants using USFDA/CE approved software, getting surgeon’s approval, followed by building implants through 3D printing, performing post-processing operations, and lastly carrying out quality control. This process totally eliminates the step of re-working on the frameworks of the models and implants. Therefore, 3D printing technology is considered as the most accurate method in the market.

With high-tech post processing tools and 3D metal/plastic printing By precise cutting abilities of the PSI surgical guides, a long duration of surgery get reduced drastically to save OT time and helps to conserve the native bone tissues.

Other aspects that reflects accuracy in Incredible AM’s process is its ISO 13485 and 9001 certifications and the quality control, experienced team of medical experts, and quick turn-around time. In addition, the biocompatible materials like titanium, stainless steel, cobalt chrome and Nylon.

Benefits of Using 3D Incredible’s Surgical Guides

- Greater precision in implant positioning

- Replicate the operational plan as it is in practice

- Reduction in time of operation as well as recovery

- Decrease in the errors and in-turn the possible risks of a patient’s life

- Less requirement of instruments

Accuracy in the Surgical Procedures

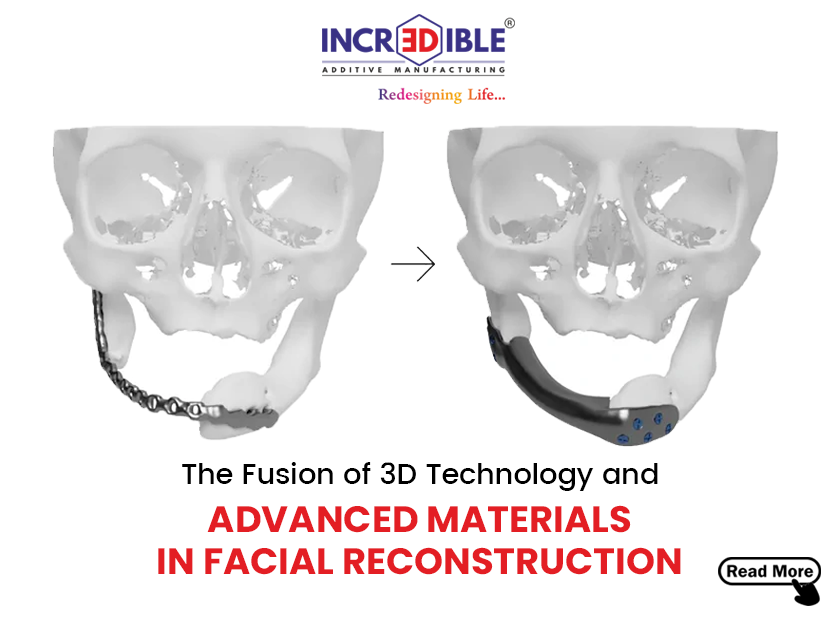

Overall accuracy in the surgical procedures is obtained by achieving perfectionat every step i.e. preparative stage, actual operation and post-operative stage. To gain placement accuracy, first CT scans are performed, and then the DICOM files are transformed into 3D models. These STL files or models a visual program to pin the placement of the implant.

Patient specific guides/instruments enable perfect restoration of the imperfect alignment or the deformed angulation of the bones and joints. The practical implementation of this technology has modified the process of operation/surgery. It provides a significant amount of precision in the agreement of the 3D implants. . It is a perfect fit with the patient’s native anatomy because the implant’s size and designis already defined during the pre-operative stage. This is resulting in the creation of optimum sized implants for every patient.

Conclusion

Using additive manufacturing, Incredible AM Pvt. Ltd. creates marvelous patient specific surgical guides that can be used for pre-surgical planning as well as the actual surgery.