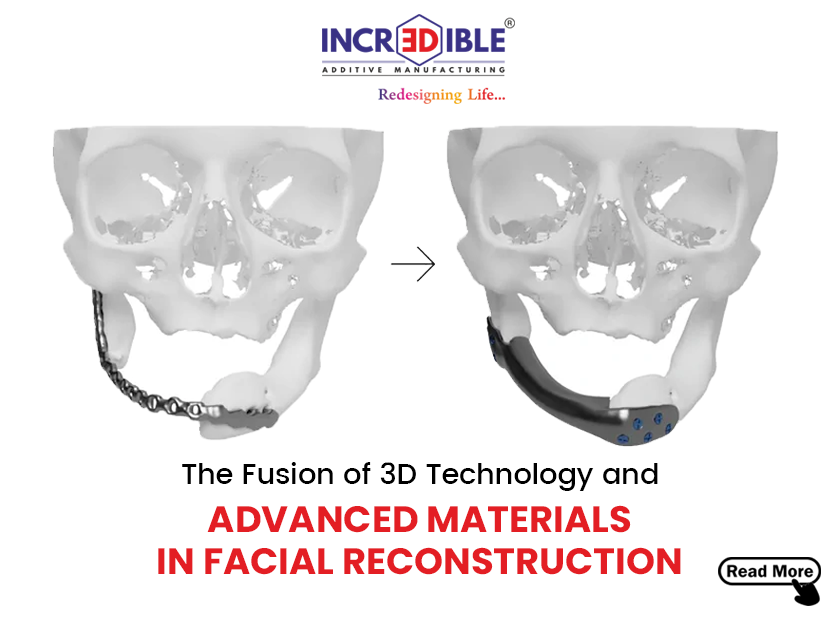

Accidents and other unfortunate circumstances might result in various maxillofacial defects, including orbital wall fractures. Orbital wall fracture causes several structural and functional defects such as increased orbital volume, tissue herniation into the maxillary sinus, fat atrophy, loss of ligament support, and scar contracture leading to enophthalmos and diplopia. Reconstruction of such defects always poses a challenge due to the loss of anatomical landmarks such as the posteromedial orbital bulge and orbital apex. The traditional reconstruction techniques are not efficient enough to correct the defects. In most cases, increased orbital volumes remain even after treatment.

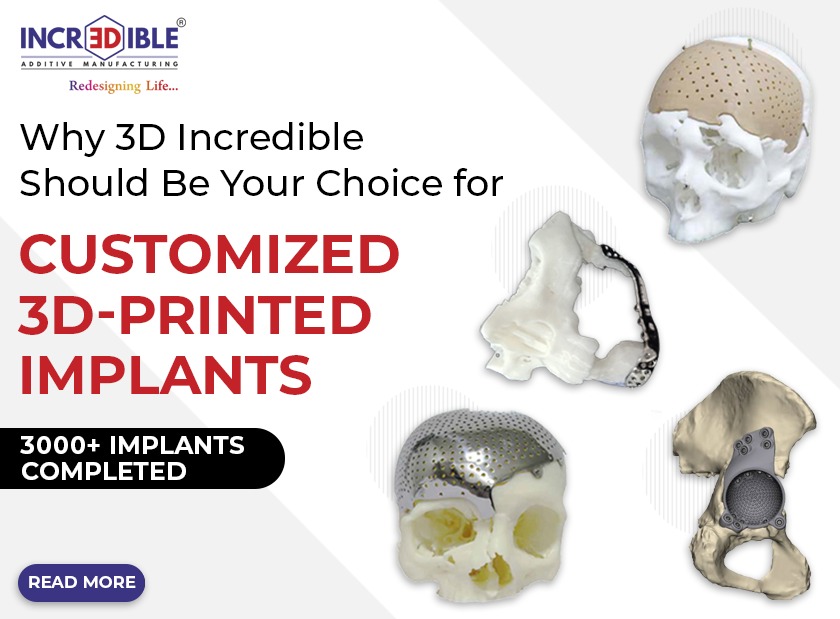

The novel technique of 3d printing is proving a boon in the medical field by providing patient-specific implants for better aesthetic and functionality of the damaged or defective part. 3D Incredible AM Pvt Ltd, based in Pune, is a pioneer in 3d printing in India and is a well-known manufacturer of 3d implants, bio-models along with 3d printed surgical guides. In this blog, let’s learn about how 3d printed orbital implants are best for volume correction.

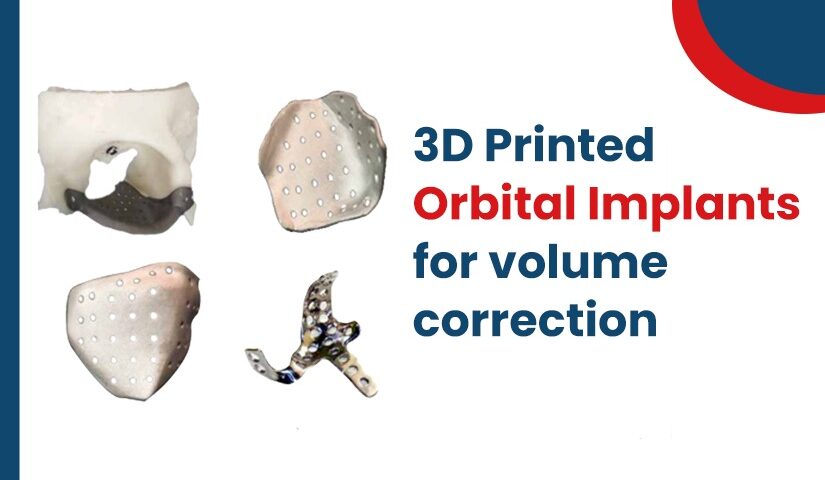

3D printed orbital implants

To get 3d printed orbital implants, designing engineers prepare a design through the digital imaging of the data obtained from the patient’s computed tomography (CT) scan. We then create a 3d model through rapid prototyping technology. This model is then used to create the implant by mirroring data from the unaffected part of the orbit, followed by the reconstruction process.

Advantages of the technique for patients

• A true-to anatomical repair

• Restoration of orbital volume

• Superior ophthalmological rehabilitation

This novel technique not only is beneficial for patients but also helps during surgery by simplifying the insertion by the precise fit and spending less operating time during the reconstruction process.

Why should you choose 3D Incredible for 3d printed orbital implants?

At 3D Incredible, we know human anatomy is specific for each individual, and therefore reconstruction requires personalized treatment. Hence, we provide custom-made orbital implants that exactly fit the anatomy of an individual.

Uses the best material

Our company makes use of Ti6AI4V ELI alloy, the most widely used biocompatible material for producing implants. This robust, infection-resistant, and radiolucent alloy of Titanium has great biocompatibility, low thermal expansion, and low thermal conductivity. The orbital implants made of Titanium alloy have a very high strength-to-weight ratio, and that makes them incredibly light.

State-of-the-art manufacturing unit

The state-of-the-art infrastructure maintained at Pune has the latest and the most advanced technology to provide a specific and accurate solution for additive manufacturing technology. The unit designed and built as per FDA requirements has 2 Reinshaw AM 400 metal printers, which are currently the best metal printing machine available to handle any complex tasks, including the orbital implant.

Well-equipped Software Designing Lab

Designing patient-specific orbital implants is an intricate process. We use US FDA and CE-approved licensed software such as Materialise Mimics, 3Matics, Magic, Quant AM, and NX-Siemens to accomplish complex tasks.

Quality assurance

At Incredible, we care for maintaining quality and regulatory requirements. We manufacture medical devices in 10,000 cleanroom, which is equivalent to ISO 7. An ISO 13485:2016 certified company, we conduct validation/calibration of equipment regularly through NABL accredited laboratory to ensure the quality of the product.

Work with experienced professionals

At 3D Incredible, we have experienced professionals: engineers, designers, biomedical engineers, and doctors who work as a team to manufacture high-quality, world-class customized 3d printed orbital implants.

Shortest turnaround time

In India, we have earned the reputation of offering the shortest turnaround time. Our company makes use of the latest 3D printing technology to manufacture customized orbital implants at a fast pace that facilitates us to deliver the implants on time.

Cost-effective price

At 3D Incredible, we provide a complete solution from scanning to manufacturing custom-made orbital implants at cost-effective prices.

Conclusion

With wide experience and a worldwide client base, we’re reputed to provide the best aesthetic and functionality to the disfigured or damaged parts of the body. Similarly, we produce the best 3d printed orbital implants to correct the orbital volume. If you’re looking for customized orbital implants, our brand Confidence for OMF implants is capable to fulfil your demand. Contact us for all your queries.