3D imprinting was introduced in the field of additives manufacturing in the 1980s. However, it gained popularity in the 2000s, but according to the Forbes 2014 review, the 3D-printing industry developed 35.2%. It is estimated that by 2021, it will become a regular practice in the medical profession.

It is gaining a lot of appreciation in the medical field. Medical experts are widely using 3D printing technology to gain perfection in treating various deformities. This technology enables doctors to create patient specific implants. It can be a favourable choice for doctors in case of every kind of implants.

These 3D implants are more efficient, have a faster recovery span, and it also increases the quality of life for the patients. This highly advanced technology helps in making the perfect replicas according to the patient’s needs. Enabling the doctors to make the optimum implants and provide flawless treatment.

Advantages of 3D Printed Implants

Less Surgery Time –

During a traditional procedure, the doctors have to perform pre-op assessments and intra-op procedures that consume a lot of time. But in the case of 3D implants, you already get the best fit and it cuts off some intra-operational procedures as well as the attempts to place the implants that lessen the operating time as well as the risk of infection.

Pre-Planned Operations –

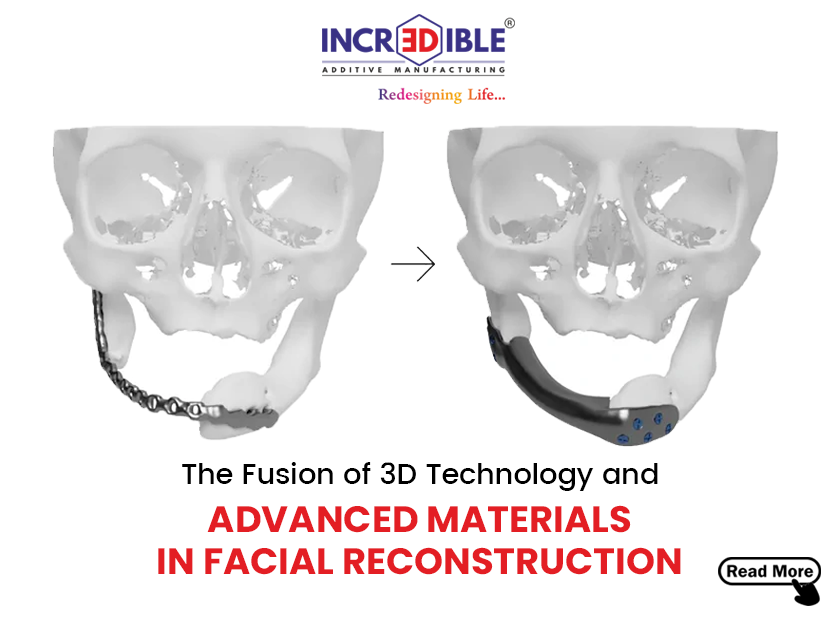

Nowadays doctors can pre-plan the operations using the 3D CAD anatomy models. They get an idea of how and where to fix the implant. No matter how complex the patient’s situation Their anatomy is studied thoroughly and then designed accordingly with no errors. Pre-planning helps the doctors to perform the operations quickly and confidently; with fewer attempts, the patient’s body is prevented from any possible damages.

Faster Recovery –

Since the implants fit flawlessly and are made by biocompatible materials it osseointegrates faster and the recovery is fastened. The patient has to spend less time in the hospital. This saves up the resources of the hospitals and the patient’s family. And doctors can attend more patients.

Increases the Success Rate –

Since the PSI 3D implants are matching to patient’s anatomy and are precisely designed, less surgery, operation, and recovery time. This results in longer &stable fixation of implants. The 3D CAD anatomy models are helpful to surgeons to plan complicated surgeries well in advance, . The success rates of the operations are higher with a clear vision of every parameter of the procedure.

Uplifts the Reputation and Recognition –

So many people believe in the technology of 3D printing as it is proving to be favourable in every aspect. Especially Patients can have full confidence on the outcome after the operation. Hospitals are being appreciated for being technologically advanced and the number of successful operations.

Conclusion –

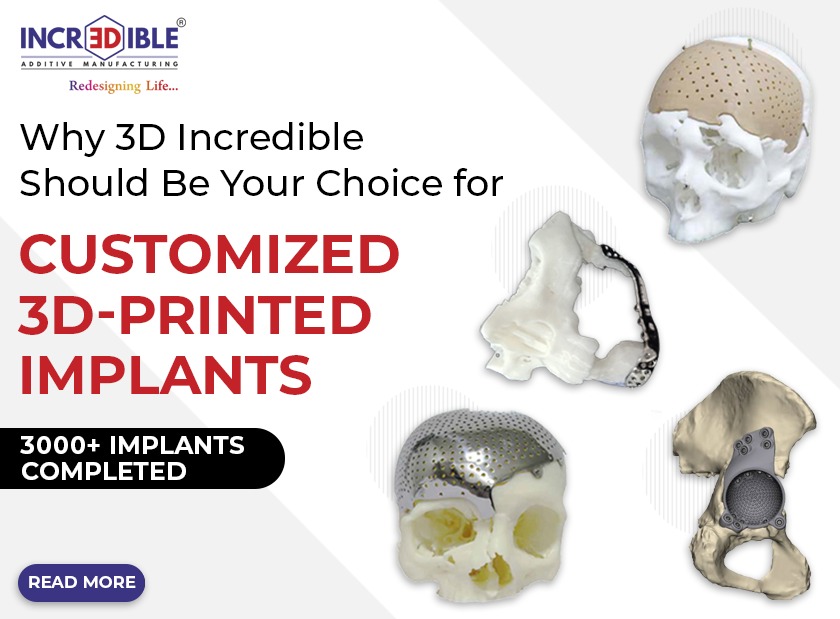

As the demand for 3D medical implants are constantly growing throughout the globe, Incredible AM Pvt Ltd has bonded its fold to provide world class solution to health industry.

The implants can be used to create cranial implants, hip replacements, ankles, and spinal parts, and knees, external prosthetics. These implants are made using two different alloys that include Titanium (Ti6Al4V) Cobalt-Chromium (CoCr). There are various tests that are mandatory before the creation of 3D implants. Tensile testing, bioburden test, chemical analysis test, density measurement test, stability test, and biological evaluation test which needs to be conducted on medical implants before they reach the doctor

These high quality customized implants are manufactured at Incredible AM Pvt. Ltd. facility which ISO 13485 approved facility.