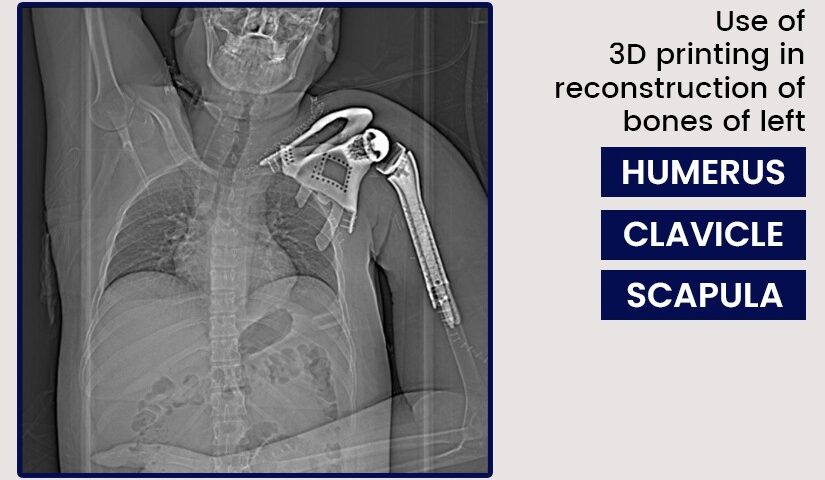

Customized ortho implant solution is now commonly used in limb salvage surgery. 3d-printed patient-specific implants are created to treat people with distorted anatomy caused due to massive resection of tumors or cancerous bones. Incredible AM, based in Pune, manufactures customized implants for long bones and limbs under the brand name LimbSal Ortho. Customized implants are used in treating patients with osteosarcoma, Ewing sarcoma family of tumors, chondrosarcoma, and more where anatomy gets distorted and loses its functionality due to the removal of cancerous cells or tumors from the body part. In this blog, let us learn about how 3D Incredible creates the 3d-printed implants that are used in the reconstruction of bones of the left humerus, clavicle and scapula.

Creation of a 3d-printed patient-specific implant for the reconstruction of bones of the left humerus, clavicle and scapula by Incredible

To demonstrate how 3D Incredible creates customized implants, let us take the example of a 29-year-old male from Bangalore who benefitted from our LimbSal Ortho.

The patient complained of mass and pain in his left scapula/humerus region. After histopathology, the doctor determined that the patient had recurrent chondrosarcoma of the left proximal humerus. Dr.PramodChinder, a renowned onco-orthopedic surgeon, and Dr. Suraj from The Yellow Ribbon Clinic–HCG Hospital Bangalore decided to remove the tumour first and then reconstruct the scapula, clavicle, and humerus bone.

Due to the extensive extent and size of the lesion, the surgery to treat the bone is performed in two parts. On day 1, a wide resection of the tumor in the left proximal humerus that encases the clavicle and scapula is performed. The proximal half of the humerus, lateral 2/3 of the clavicle, and upper half of the scapula areremoved in addition to the tumor mass. Day 2 involves reverse shoulder arthroplasty and shoulder reconstruction using 3D-printed humerus, scapula, and clavicle implants.

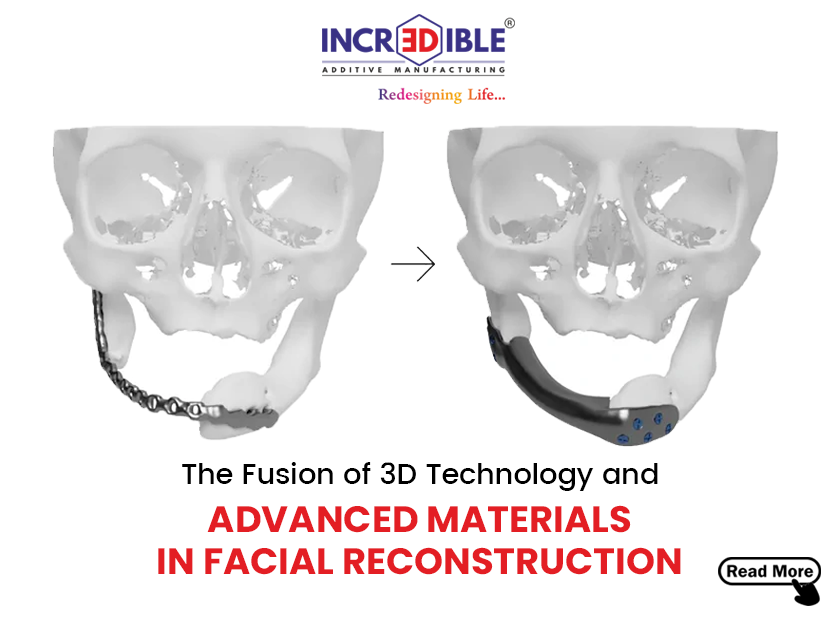

The team of Incredible discusses the design and the entire manufacturing process with the surgeon. With the aid of the US FDA & CE approved Materialize Mimics software, the process starts with surgical planning and case stimulation by superimposing CT & MRI DICOM data. Once the planning is complete, the customized implants are made to complement and match the specifications of the reverse arthroplasty shoulder joint implants to ensure the best possible arm articulation functionality. The doctor’s suggestions, along with those of the Incredible design team, are helpful in finishing the design.

Advantages of 3d-printed implants

The benefits of 3d-printed implants for the reconstruction of bones of the left humerus, clavicle and scapula are many.

First, the entire system allows for easy attachment to the implant and bone and provides directional movements.

Another advantage of a 3D-printed implant is its customization, which not only resembles the specific anatomy required but also improves fixation. To assess the implant’s strength, stability, and functionality, finite element analysis is used.

Benefits of LimbSal Ortho Implants

The implant is made in accordance with ISO 13485 specifications and tested for maximum safety and accuracy of fit.

Ti6Al4V-ELI is used to create the implant in accordance with patient-specific anatomical requirements, contours, and bone thickness.

Because the standard implant did not need any additional adaptation on the OT table, the 3D Incredible customized implant helps to reduce the OT process.

The plant, machinery, and processes at Incredible AM Pvt. Ltd. are rigorously tested and validated in order to guarantee the quality and safety of the Implant.

Conclusion

Incredible AM Pvt Ltd is the first and only firm in India to use medical 3D printing in a top-notch facility. It is built according to FDA standardsand has ISO 9001 and ISO 13485 certifications. In addition to the best team of doctors, engineers, biomedical engineers, CAD designers, and medical consultants who are there to provide outstanding services,the company also has some key features that include a Class 10000 clean room, US-FDA-approved software, and cutting-edge equipment. Complete validation and tests are also conducted to certify the process and product. Incredible offers customized implants, standard implants, bio models, and cutting guides.

To obtain customized implants, connect with us.