A significant technological innovation, 3D printing has made it feasible to customize, prototype, produce, and conduct research in the realm of medicine. Additionally, this technology’s application in the medical profession might be utilized to eliminate organ transplants, speed up operations, make pricey surgical equipment more accessible, and improve the quality of life for patients who rely on prosthetic limbs.

The process of 3D printing, also known as additive manufacturing, was invented in the 1980s. It involves transforming a digital model or blueprint into a new version of the subject, which is subsequently printed in numerous layers on the right material.

One of the numerous domains in which the approach has been applied in medical technology. Using medical imaging methods like computed tomography (CT) scans, the original digital model is usually produced using a 3d printer.

Incredible AM Pvt Ltd, specializing in additive manufacturing, offers 3D printing services to a range of sectors, including the healthcare industry. The top five applications of 3D printing in the medical field are listed below.

Top five applications of 3d-printing in medical science

Creation of 3d-printed tissues and organs

Tissues and organs can now be produced using 3D technology. Because it tackles any potential moral and ethical difficulties related to traditional transplant processes, this is extremely intriguing and pertinent to the field of transplants. Acceptance is further boosted by the use of the patient’s own cells in the customized organ development.

Successful kidney transplants, heart transplants, limb replacements, and skin tissue repair and rebuilding have all been made possible by the use of 3D printing in medicine. Moreover, the ability to mend bones and muscles has been made possible by the development of orthopedic implants using 3D printing.

In an effort to comprehend how tumors grow and develop and ultimately discover a solution, research into illnesses like cancer has been accelerated by the capacity to 3D print tissue cells and organs.

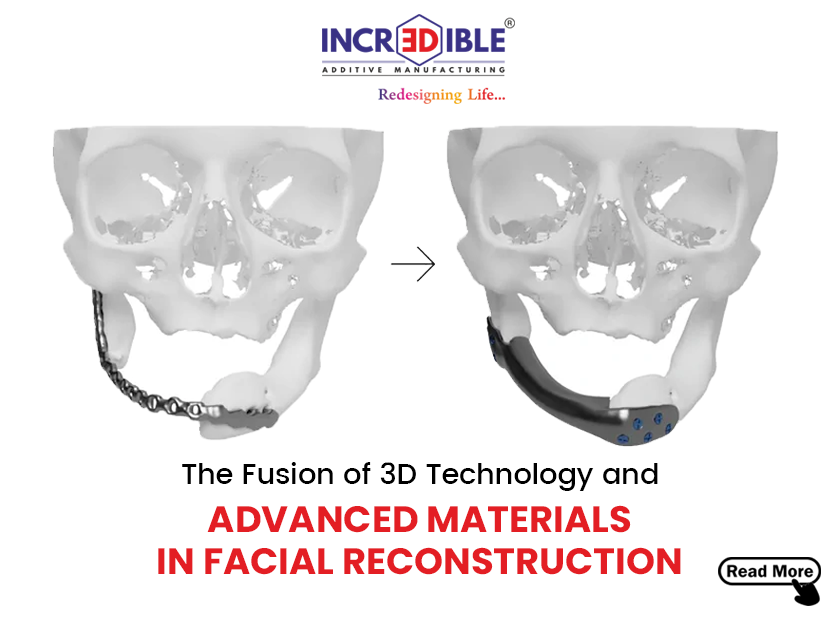

Creation of 3d-printed bio-models

An important area where 3D printing is transforming medicine is surgery planning. Before the real operations, mock surgery is performed on 3D-printed bio models to get acquainted with the complications of the surgery beforehand. This makes real surgery a lot more efficient and accurate than relying only on X-rays, CT scans, and MRIs. In the end, it has been demonstrated that this strategy speeds up procedures and lessens patient trauma.

The scanning and healing of fractures and cracks, as well as operations for birth complications, heart transplants, and operations to treat birth complications all involve the use of this technology. It also helps to evaluate an organ’s suitability for use through reproduction.

Another benefit is that the surgeon may physically work with and view the patient-specific anatomical model. By doing this, they can have a more comprehensive understanding of the patient’s particular anatomy and better prepare for the treatment. With this approach, the patient’s recovery is more likely to be successful. Surgery simulation and planning using 3D printing have the potential to significantly reduce costs and time while also improving success rates.

Another benefit is that the surgeon may physically work with and view the patient-specific anatomical model.

Creation of affordable and customized surgical tools

Sterile surgical tools like cutting tools, jigs, forceps, hemostats, scalpel handles, and clamps can be produced using 3D printers.

Because 3D printing is based on the age-old Japanese origami craft, it can also make accurate objects that are very small in addition to manufacturing sterile equipment. These instruments enable surgeons to operate on small areas without putting the patient’s health in peril.

One of the key benefits of employing 3D printing to manufacture surgical tools over more traditional manufacturing processes is the much-decreased production costs.

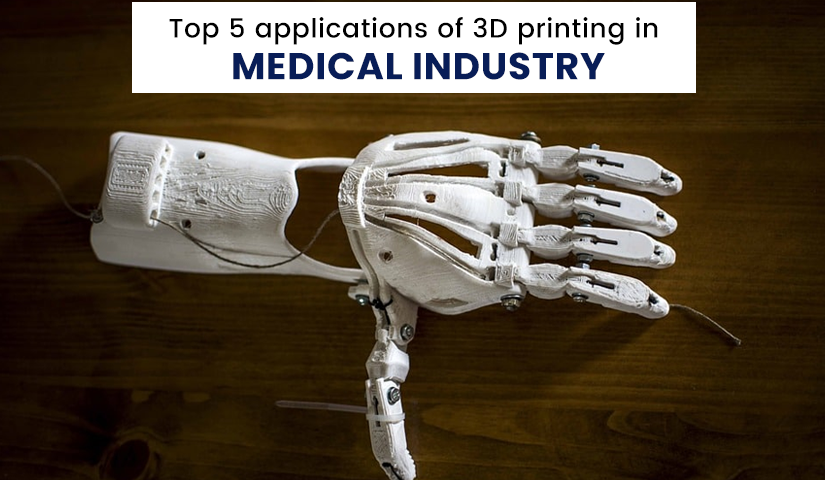

Creation of customized prosthesis and implants

Prosthetic limbs and patient-specific implants are being made easier with the help of medical 3D printing. The reputation of conventional prostheses is that they are both exceedingly expensive and painful for the amputee.

3D printing addresses this issue. The ultimate goal is to develop affordable and pleasant prostheses tailored for specific patients. This goal is already a reality thanks to various projects on 3D-printed prosthetic arms and legs!

The provision of prostheses or the replacement of limbs to war refugees and numerous other victims of natural calamities has advanced significantly.

Also, due to their lower price tags, these goods are particularly appropriate for usage with kids who quickly outgrow their prosthetic limbs.

The same is true for customized implants that perfectly fit the patient’s anatomy and provide them with desired functionality and aesthetic.

Creation of 3d-printed medicines

Another significant use of 3D printing is in the pharmaceutical industry. Pharmaceutical companies are utilizing the technology to produce medicines that are more cost-effective than conventional medicines. A three-dimensional model of a drug’s molecular structure is made using 3D printers and is subsequently reproduced in plastic or other materials. Using the technology, pharmacists can develop customized drugs just for your need.

Conclusion

Medical 3D printing, which uses cutting-edge healing technology, is quickly taking over the medical sector. The range of technology used in the medical industry is continually expanding thanks to ongoing research.

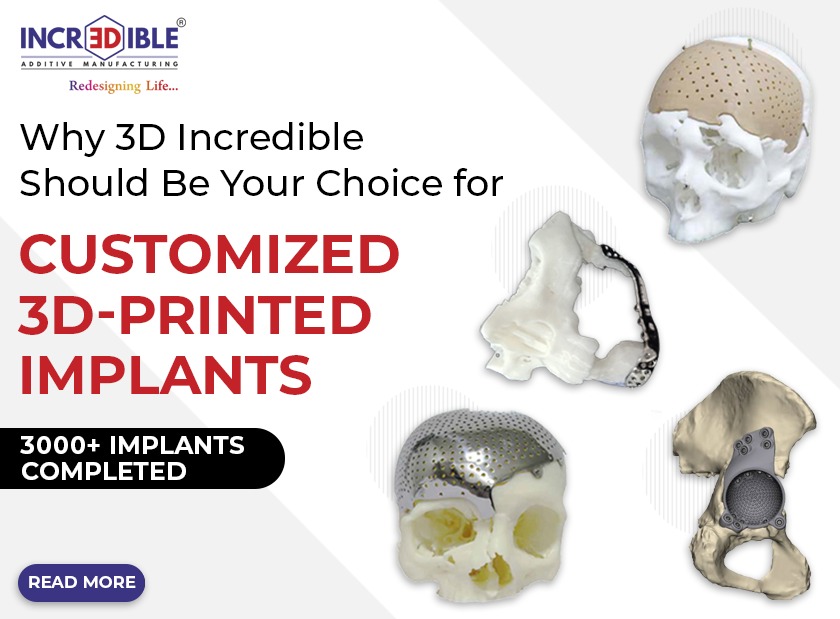

To develop and create precise implants, a knowledgeable team at 3D Incredible AM Pvt Ltd works together with physicians and surgeons. We are dedicated to helping people all across the world and have more than 45 years of combined experience. We can quickly and accurately produce complex designs thanks to modern 3D design tools and 3D printing technology. We are known in India for providing the shortest response times. We have everything 3D-printed in one place, including implants, models, and equipment. Thus, if you need help, contact us.