3D printing is a great technological advancement that has made customization, prototyping, manufacturing, and research possible in the field of medicine. Additionally, this technology integrated into the medical field could be used to replace human organ transplants, expedite surgical procedures, make expensive surgical instruments more affordable, and enhance the lives of people who depend on prosthetic limbs.

3D printing, also referred to as additive manufacturing, was first created in the 1980s. It entails creating a new version of the subject from a digital model or blueprint that is then printed in multiple layers on the appropriate material.

Medical technology is just one of the many fields in which the technique has been used. The original digital model is frequently created with a 3d printer using medical imaging techniques like computed tomography (CT) scans.

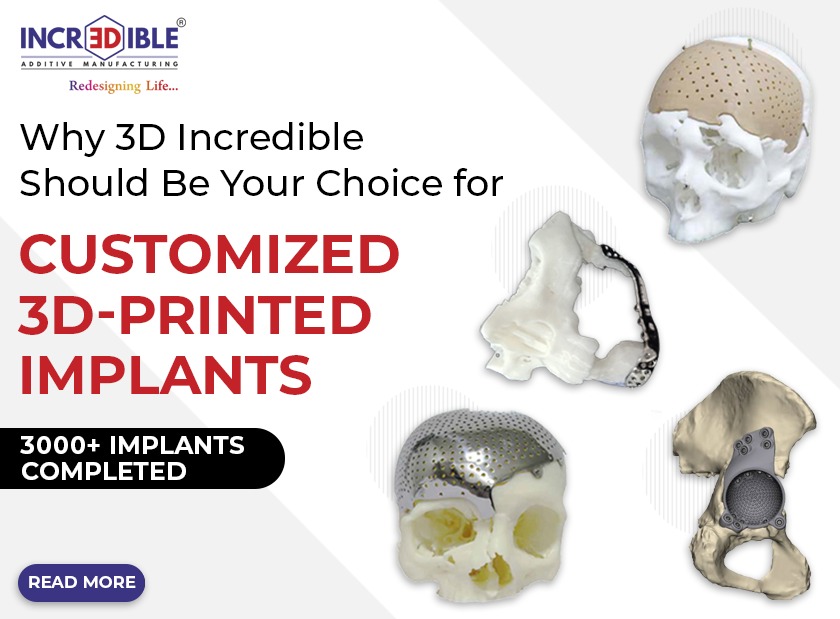

Incredible AM Pvt. Ltd is a Pune-based additive manufacturing company providing 3d printing services to various industries, including healthcare. Below, we have compiled the four top benefits of 3d printing in the medical industry.

Top 4 applications of 3d printing in medical industry

3D printed tissues and organs

Organs and tissues can now be 3D printed as well. This is particularly interesting and relevant to the field of transplants because it addresses any moral and ethical concerns that might be associated with conventional transplant techniques. Additionally, because the patient’s own cells are used in the customized organ development, acceptance is increased.

The use of 3D printing in medicine has enabled successful kidney transplants, heart transplants, limb replacement, and skin tissue repair and reconstruction. Additionally, the creation of orthopedic implants using 3D printing has made it possible to repair bones and muscles.

The ability to 3D print tissue cells and organs has sped up research into conditions like cancer in an effort to understand how tumors grow and develop and ultimately find a cure.

Surgical preparation using 3d printed models

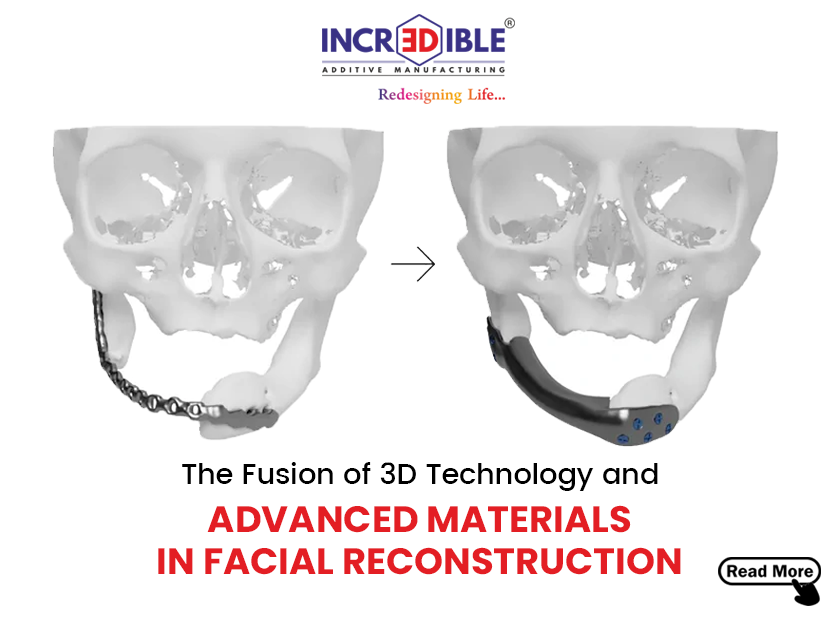

Surgery planning is one area where 3D printing is revolutionizing medicine. Replicated patient-specific organs are being used for practice and preparation procedures prior to the actual complex operations using 3D printing. Compared to relying solely on X-rays, CT scans, and MRIs, the application is significantly more effective and accurate. In the end, this approach has been shown to expedite processes and reduce patient trauma.

This technology is used in procedures like spinal repair, operations for birth complications, heart, and vital organ transplants, and scanning and mending of fractures and cracks. Assessing an organ’s suitability for use through replication also helps.

The surgeon’s ability to physically manipulate and see the patient-specific anatomical model is another advantage. By doing so, they can learn the patient’s precise anatomy from a variety of perspectives and better prepare for the procedure. The patient’s recovery is more likely to be successful with this strategy. Using 3D printing for surgical simulation and planning has the potential to save a significant amount of money and time in addition to increasing the success rate.

The surgeon’s ability to physically manipulate and see the patient-specific anatomical model is another advantage.

Low-cost surgical tools

3D printers can be used to create sterile surgical instruments like forceps, hemostats, scalpel handles, and clamps.

In addition to producing sterile tools, 3D printing can also create precise objects that can be made to be very small because they are based on the ancient Japanese art of origami. These tools allow surgeons to work on small areas without endangering the patient’s health.

The production costs are significantly lower when using 3D printing to create surgical instruments as opposed to more conventional manufacturing techniques, which is one of the main advantages.

3d printed customized prosthetics

Medical 3D printing is assisting in the creation of prosthetic limbs. Traditional prostheses have a reputation for being both very expensive and uncomfortable for the amputee.

This concern is being addressed by 3D printing. The ultimate objective is to create cost-effective, comfortable prostheses that meet the needs of individual patients. This objective is already a reality thanks to the numerous projects on 3D printed prosthetic arms and legs!

A lot of progress has been made in providing prostheses or replacing limbs to refugees from war and numerous other victims of natural disasters.

Additionally, these products are especially suitable for use with children, who quickly outgrow their prosthetic limbs due to their lower price points.

Conclusion

Medical 3d printing offering new-age healing technology is fast becoming an indispensable part of the medical industry. Ongoing research is further widening the scope of the technology in the medical field.

An expert team at 3D Incredible AM Pvt. Ltd works closely with doctors and surgeons to design and produce precise implants. We have more than 45 years of combined experience, and we are passionate about assisting patients all over the world. Modern 3D design software and 3D printing equipment enable us to quickly and accurately create complex shapes. In India, we are renowned for having the quickest turnaround times. We offer all 3D printed implants, models, tools, and equipment in one place. So, if you require assistance, we are here to provide it. Connect with us.