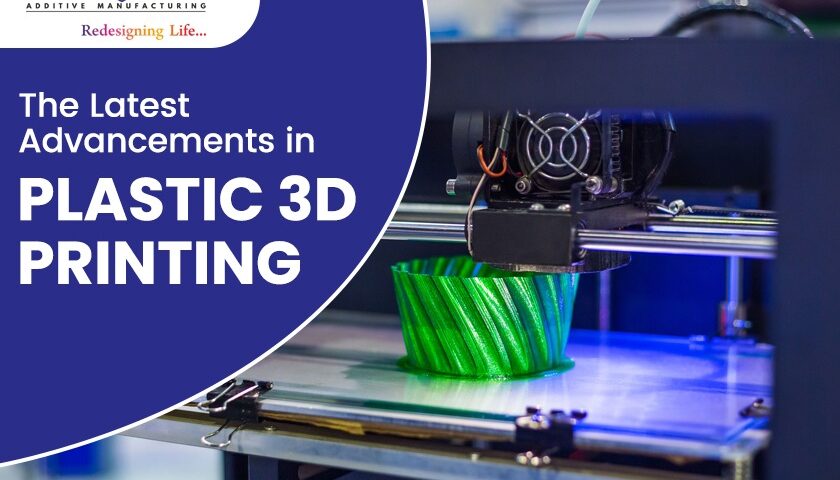

The Latest Advancements in Plastic 3D Printing

3D printing technology has advanced at an unprecedented rate, transforming various industries. Among the numerous 3D printing applications, plastic 3D printing stands out as a game changer, providing versatility, cost-effectiveness, and innovation. The most recent advancements in plastic 3D printing have pushed the boundaries of what was previously thought possible. This blog will examine the innovative technology shaping the future of plastic 3D printing.

High-Speed 3D Printing

Earlier, 3D printing was a slow process. However, recent technological advancements have dramatically increased printing speeds while maintaining print quality. It is possible due to improved printing algorithms and faster curing processes. This high-speed plastic 3D printing is crucial for industries that require rapid prototyping and large-scale production.

Advanced Materials

Material selection is a crucial factor in 3D printing. Recent advancements have broadened the range of printable materials, providing engineers and designers with unprecedented options. New high-performance polymers, composite materials, and bio-based plastics are joining traditional plastics like ABS and PLA on the market. These materials have increased strength, durability and sustainability, making them suitable for wide industrial applications.

Multi-Material Printing

The ability to print with multiple materials in a single process is one of the most exciting advancements in plastic 3D printing. This capability enables the development of complex, multi-functional objects with varying properties. Combining rigid and flexible materials in a single print allows the production of intricate designs previously difficult or impossible to achieve. It opens up new opportunities for use in industries such as aerospace, healthcare, and consumer electronics.

Improved Resolution and Precision

Advances in printer hardware and software have improved the resolution and precision of plastic 3D printing. Smoother, more detailed prints result from finer layer resolutions and improved calibration techniques. It is useful in industries where precision becomes critical, such as dentistry and medicine. Creating complex, high-resolution parts improves the overall quality and usability of 3D-printed objects.

Continuous Printing

The development of continuous printing technologies is another breakthrough in plastic 3D printing. Continuous printing eliminates pauses, allowing the creation of objects without visible layer lines. It improves the structural integrity of printed objects while also speeding up the printing process, making it more efficient and suitable for mass production.

Conclusion

The advancements in 3D plastic printing catapult the technology into a new era of possibilities. These innovations reshape modern manufacturing, prototyping, and product development, from high-speed printing and advanced materials to multi-material capabilities and improved resolution.

Incredible AM Pvt Ltd in Pune is a pioneer in 3d printing in India. At the world-class manufacturing facility in Koregaon, Pune, we deal in SLS, FDM, SLA and MJF 3D printing methodologies. Besides, we use different 3d printing materials, such as nylon, PA, ABS, PLA and more. We provide the best possible 3d printing solutions to several industries, including defence, aerospace, healthcare and more, at the lowest price, highest quality and fastest lead time.