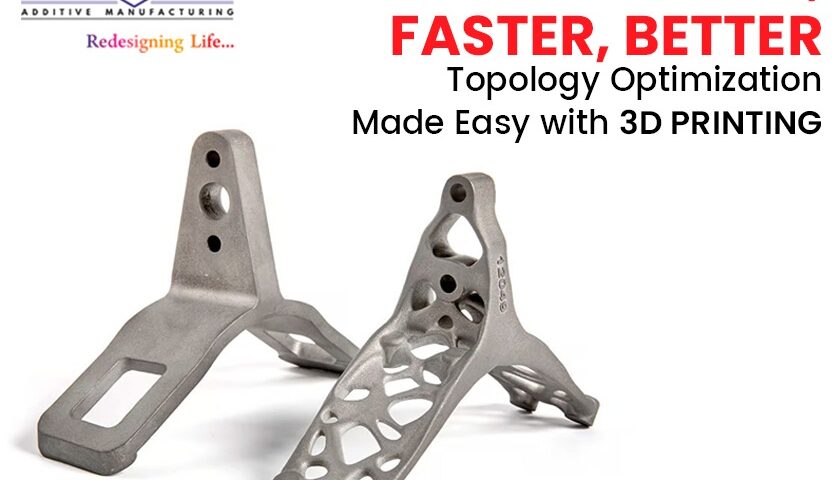

Sharper, Faster, Better: Topology Optimization Made Easy for 3D Printing

The innovative manufacturing technique of 3D printing is evolving rapidly. With advancing technology, designers and engineers seek ways to optimize their creations. Topology optimization is a ground-breaking approach that has the potential to revolutionize the way we design and manufacture objects using 3D printing technology. It determines the most efficient material distribution to achieve the desired mechanical properties while minimising weight and material usage. This blog will explore how topology optimization makes the process sharper, faster, and better.

Sharper Designs

Topology optimisation analyses the loads and constraints on a structure using advanced algorithms and simulations, resulting in sharper and more efficient designs.

Designers can use topology optimisation to create intricate, complex geometries that would be difficult, if not impossible, to imagine using traditional methods. As a result, the design is aesthetically pleasing and functionally optimised.

Faster Prototyping

Time is crucial. By automating the design exploration phase, topology optimisation significantly speeds up the prototyping process. Rather than manually iterating through multiple designs, the algorithm searches design space for the most efficient configurations.

Engineers and designers can quickly test and validate their concepts with an accelerated design process. Rapid prototyping is becoming more accessible, allowing faster iteration cycles and shorter time-to-market for innovative products. As a result, companies can remain competitive in today’s fast-paced market.

Better Performance

Topology optimization improves the structural performance of 3D-printed objects. The final product achieves the desired strength and stiffness characteristics while minimising unnecessary weight by optimising the material distribution. It results in efficient material usage, improving the overall performance of the printed object.

Additionally, topology optimisation enables the creation of lightweight structures with intricate internal geometries that would be difficult to achieve using traditional manufacturing methods. It improves performance and opens new opportunities for innovative designs in various industries.

Applications across Industries

Topology optimisation impacts various industries, from aerospace and automotive to healthcare and consumer goods. For example, weight reduction achieved through topology optimisation in aerospace can result in significant fuel savings and improved efficiency. Customized and optimized implants in healthcare improve patient outcomes.

Conclusion

Topology optimisation stands out as a game-changer in 3D printing technology. Its ability to create sharper designs, faster prototyping, and better-performing objects is changing how we think about product development. We can expect to see even more widespread adoption as the technology matures, pushing the boundaries of what is possible in 3D printing.

Incredible AM Pvt Ltd in Pune, the pioneer in 3d printing in India, offers 3d metal printing services to various industries. Our world-class manufacturing facility with a dedicated, knowledgeable and experienced workforce creates the best designs to suit clients’ demands. Moreover, we spend on adopting advancements in 3d technology to stay ahead in the growing competition.