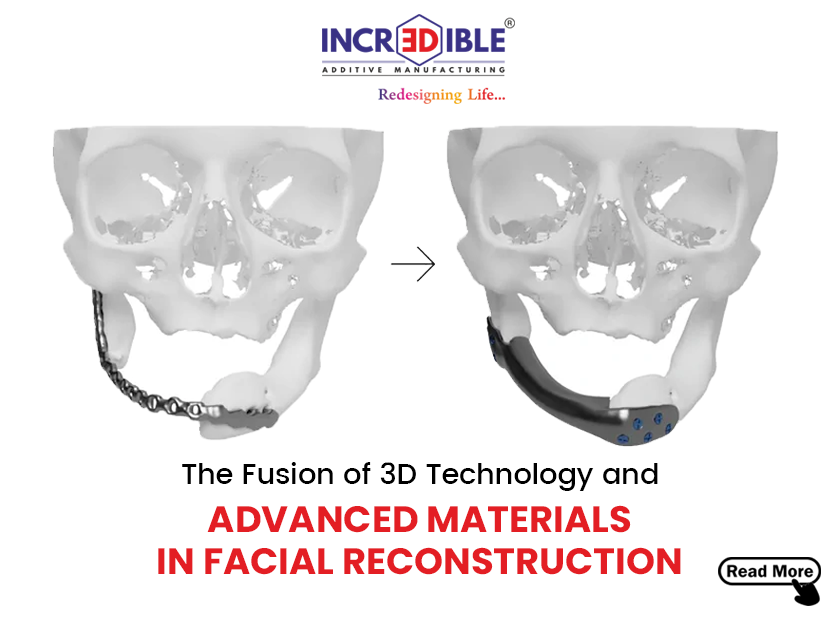

Accidents and other unlucky events may cause orbital wall fractures, among other maxillofacial abnormalities. Increased orbital volume, tissue herniation into the maxillary sinus, fat atrophy, loss of ligament support, and scar contracture leading to enophthalmos and diplopia are only a few anatomical and functional abnormalities brought on by orbital wall fracture. Due to the absence of anatomical cues like the posteromedial orbital bulge and orbital apex, reconstruction of such abnormalities is never easy. Conventional reconstructive procedures prove inefficient in correcting such flaws.

The revolutionary process of 3D printing is proven beneficial in the medical field by delivering patient-specific implants, including orbital implants, for improving the aesthetic and functionality of a damaged or defective part. Incredible 3D AM Pvt Ltd, situated in Pune, is a 3D printing pioneer in India and a well-known manufacturer of 3D implants, bio-models, and 3D printed surgical guidance. In this blog, we will learn about the creation and advantages of patient-specific orbital implants and why 3D Incredible is the best place for obtaining such implants.

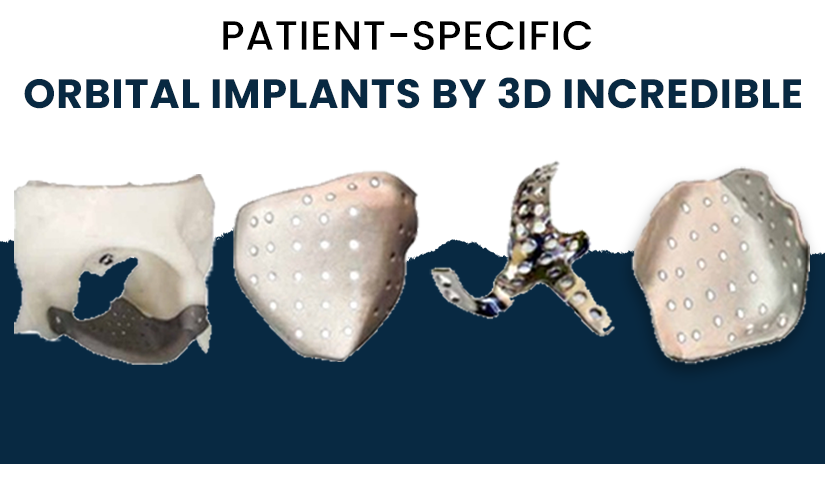

Creation of 3D-printed patient-specific orbital implants

The team of 3D Incredible discusses with surgeons about designing and creating patient-specific orbital implants. For instance, the 3D Incredible team, before creating the patient-specific orbital implant for a 45-year-old female, who had an accident leading to various bone fractures, and loss of eye movement along with the asymmetrical orbital region discussed the case with the concerned plastic surgeon Dr Dhaval Bhakt about the design and creation of customized orbital implant. The design is completed with valuable inputs from the concerned doctors and the Incredible design team.

To produce 3D-printed orbital implants, design engineers create a design using digital imaging of data obtained from a computed tomography (CT) scan of the patient. We then use rapid prototyping technologies to generate a 3D model. This model is then utilized to produce the implant by mirroring data from the unaffected region of the orbit, which is subsequently rebuilt.

Benefits of using patient-specific orbital implants

The novel technique benefits patients as well as surgeons. For patients, the technique

- provides true-to-anatomical repair

- provides superior ophthalmologic rehabilitation

- Restores orbital volume

It also helps surgeons simplify the insertion by the precise fit and spend less operating time during reconstruction.

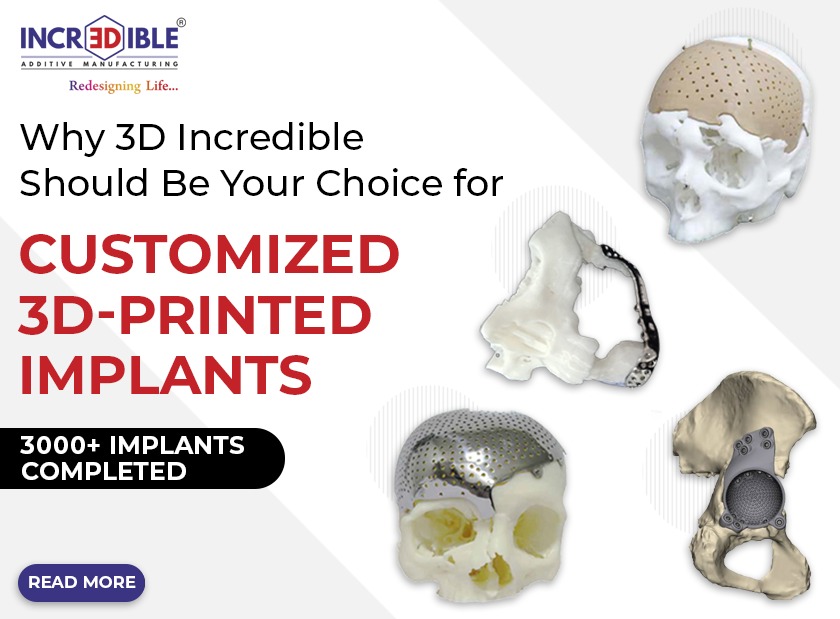

Why is 3D Incredible the best place for obtaining patient-specific orbital implants?

As a pioneer of 3d printing in India, 3D Incredible is the best place for getting patient-specific orbital implants. We understand human anatomy is specific for each individual and its reconstruction requires specialized care. As a result, we offer specially manufactured orbital implants that exactly fit each person’s anatomy.

To create the implants, we use Ti6AI4V ELI alloy, the most popular biocompatible material for making implants. With low thermal conductivity and thermal expansion, this strong titanium alloy is resistant to infection and radiolucent. The orbital implants made of titanium alloy are extraordinarily light thanks to their extremely high strength-to-weight ratio.

The state-of-the-art infrastructure in Pune is equipped with the most recent and cutting-edge technology to deliver a precise and accurate solution for additive manufacturing technology. Two Reinshaw AM 400 metal printers, the best metal printing machine now on the market for handling any difficult tasks, including the orbital implant, are a part of the unit designed and constructed in accordance with FDA criteria.

It takes a lot of work to create orbital implants that are unique to each patient. To do complicated jobs, we employ licensed software approved by the US FDA and CE, such as Materialize Mimics, 3Matics, Magic, Quant AM, and NX-Siemens.

At Incredible, we follow standards of quality and compliance. We produce medical equipment in 10,000 cleanrooms, which are ISO 7 compliant. As an ISO 13485:2016-certified business, we periodically validate and calibrate equipment at NABL-accredited labs to guarantee the quality of the final output.

We work with an experienced team of Engineers, designers, biomedical engineers, and medical specialists to create custom, high-quality orbital implants.

We have developed a reputation for having the shortest turnaround time in India. Our business uses the most recent 3D printing technology to quickly produce bespoke orbital implants, enabling us to deliver the implants on schedule.

At 3D Incredible, we offer a complete solution, from scanning to the production of custom-made orbital implants at affordable pricing.

Conclusion

With extensive experience and a global clientele, we are known for providing the best aesthetic and functionality to disfigured or damaged body parts by offering patient-specific implants, including orbital implants. If you need bespoke orbital implants, our brand Confidence can meet your needs. Please contact us for your queries.