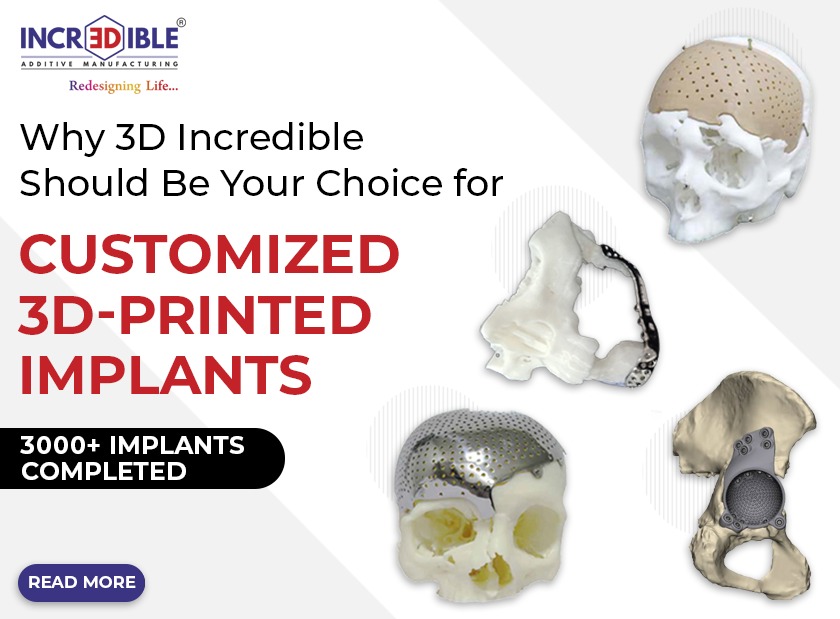

3D printing is a game-changer in the healthcare industry, transcending boundaries in the field of implants. PMMA (Polymethyl Methacrylate) is one of the materials making waves due to its unique combination of aesthetics and strength. Incredible AM Pvt Ltd in Pune is the pioneer in 3D printing in India and uses various biocompatible materials, including PMMA, to create 3D-printed implants. In this blog, let us explore PMMA 3D-printed implants, delving into the complexities of their design, the aesthetic possibilities they present, and the robust strength they bring to the table.

Precision in Design

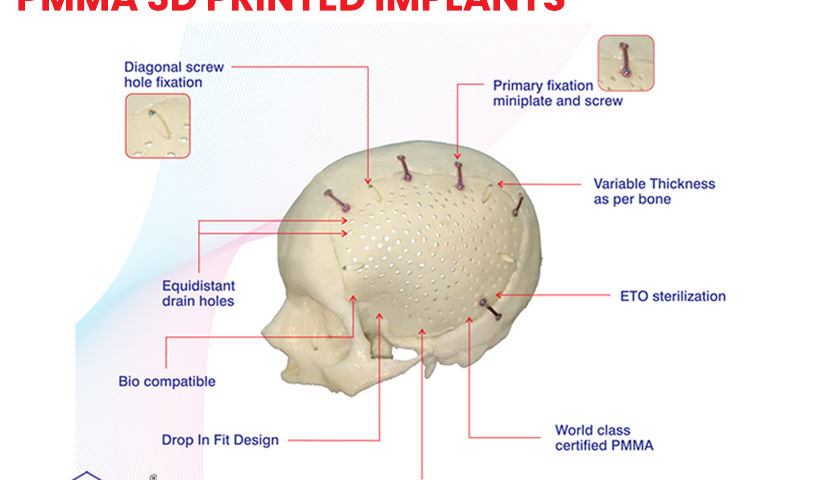

One of the primary benefits of 3D printing with PMMA is the unrivalled precision in design. At 3D Incredible, we create intricate and customised implants that are tailored to each patient’s unique anatomy. This precision improves the implants’ functionality as well as their aesthetic appeal.

Aesthetic versatility

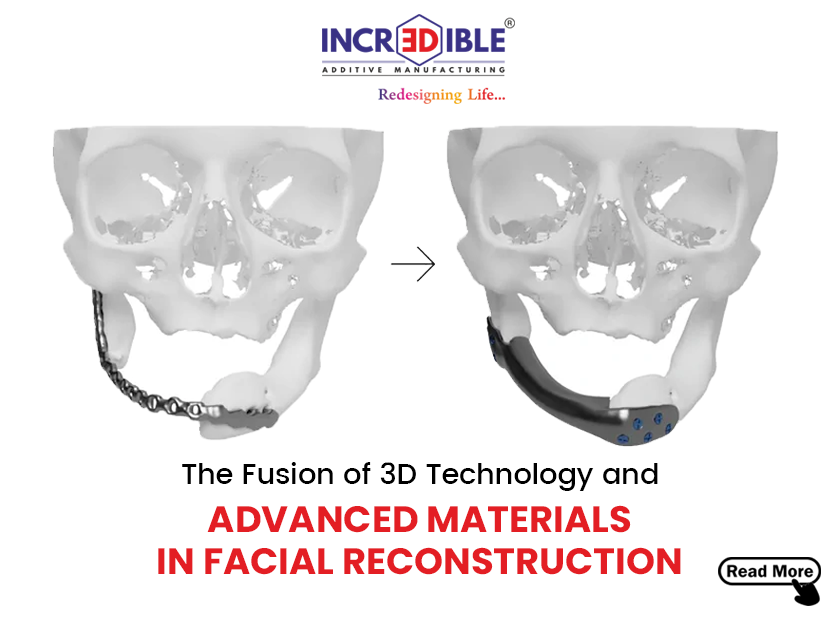

PMMA, known for its transparency and optical clarity, provides aesthetic versatility in 3D-printed implants. This is especially important in cosmetic and reconstructive implants, where achieving a natural appearance is critical. The material can mimic the visual properties of tissues, allowing it to blend in with the surrounding anatomy.

Seamless Integration

PMMA’s ability to closely resemble natural tissues goes beyond aesthetics. When our 3D-printed implants integrate seamlessly with the body’s existing structures, they promote better functionality and reduce the risk of complications. This integration is crucial for implants such as facial reconstruction and joint replacement.

Customized Implants

Every patient is unique, and PMMA 3D printing allows for implant customisation based on individual requirements. From cranial implants to prosthetic joints, the advanced technology at 3D Incredible enables the development of patient-specific solutions that ensure a precise fit and optimal performance.

Enhanced Biocompatibility

Biocompatibility is a vital consideration in any medical implant. PMMA is an excellent biocompatible material that minimises adverse reactions and promotes better body acceptance.

Optimal Mechanical Strength

While aesthetics are important, the implant’s strength cannot be overlooked. Our PMMA implants exhibit optimal mechanical strength, providing the necessary support and durability for various applications. This is especially true for load-bearing implants such as hip and knee replacements.

Reduced Production Time

3D printing PMMA implants provide a more efficient and streamlined production process; speeding up production and allowing quick customisation and adaptation to changing patient needs.

Post-Processing Technique Advancements

Post-processing methods have evolved in tandem with 3D printing technologies. The surface finish of PMMA 3D-printed implants can be fine-tuned to meet specific requirements, contributing to the final product’s aesthetics and functionality.

Conclusion

PMMA 3D-printed implants are a testament to the intersection of aesthetics and strength as we enter the era of personalised medicine. PMMA’s versatility in 3D printing holds promising developments in precision, customisation, and patient-centric solutions.

3D Incredible is your reliable partner for 3D-printed implants. At our world-class manufacturing facility in Koregaon, Pune, we create the best patient-specific implants, anatomical models, jigs and guides using the most biocompatible materials. If you require 3D-printed services or products, connect with us.