The debate between patient-specific and conventional implants has gained prominence in the rapidly developing field of medical technology, especially in dentistry and orthopaedics. Patient-specific implants are emerging as a customized and potentially ground-breaking alternative to conventional implants, which have long been the norm. In this blog, we’ll examine the distinctions between patient-specific and conventional implants, as well as learn about the benefits and drawbacks of each.

Conventional Implants: The Tried and True

For many years, conventional implants have been the mainstay of medical procedures. These implants are widely accessible and mass-produced, coming in standard shapes and sizes to suit a variety of patient needs. For many surgeons and medical professionals, they are the preferred option due to their familiarity and widespread use. However, one size does not fit all, and when a more specialized solution is needed, the shortcomings of traditional implants become evident.

Patient-Specific Implants: Tailoring Precision to Individuals

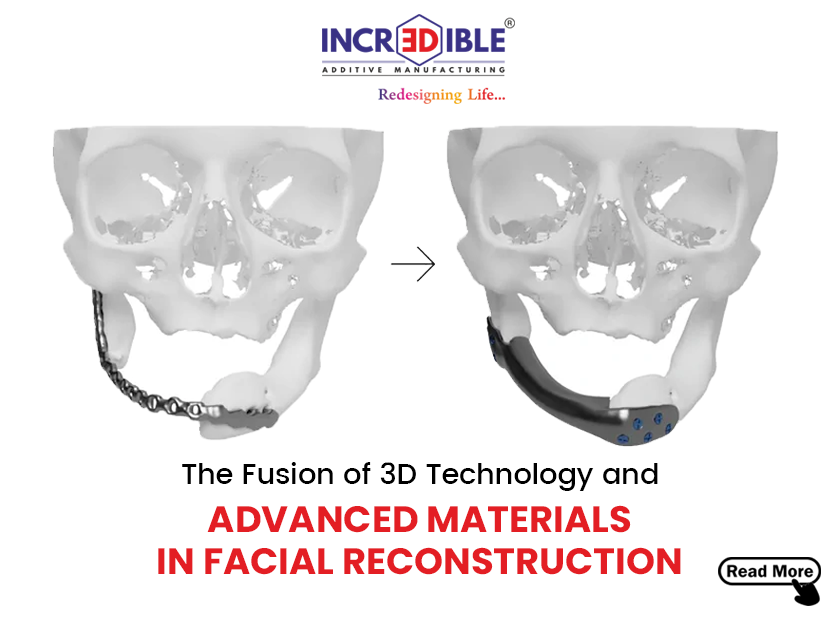

Patient-specific implants mark a revolution in the medical industry. These implants are made using modern technologies like computer-aided design (CAD) and 3D printing to match the distinct anatomical characteristics of every patient. Improved functionality, quicker recovery times, and a decreased chance of complications are just a few benefits of this degree of precision. Particularly in orthopaedic surgeries, where the complexities of bone structures necessitate a more customized approach, patient-specific implants are becoming increasingly popular.

Precision in Design and Placement

The ability to precisely design and place implants based on the patient’s anatomy is one of the main advantages of patient-specific implants. This personalization minimizes the need for significant surgical modifications, reducing the time patients are sedated and the chance of complications in general. Furthermore, implants customized for each patient can result in more normal postoperative outcomes, enhancing both functionality and appearance.

Challenges and Considerations

Although implants tailored to each patient are very promising, difficulties still exist. Compared to standard implants, the cost of developing and implementing such customized solutions can be much higher. Furthermore, design and production may take longer, potentially affecting urgent cases. Research is still being done to determine the long-term efficacy and durability of patient-specific implants in comparison to conventional options.

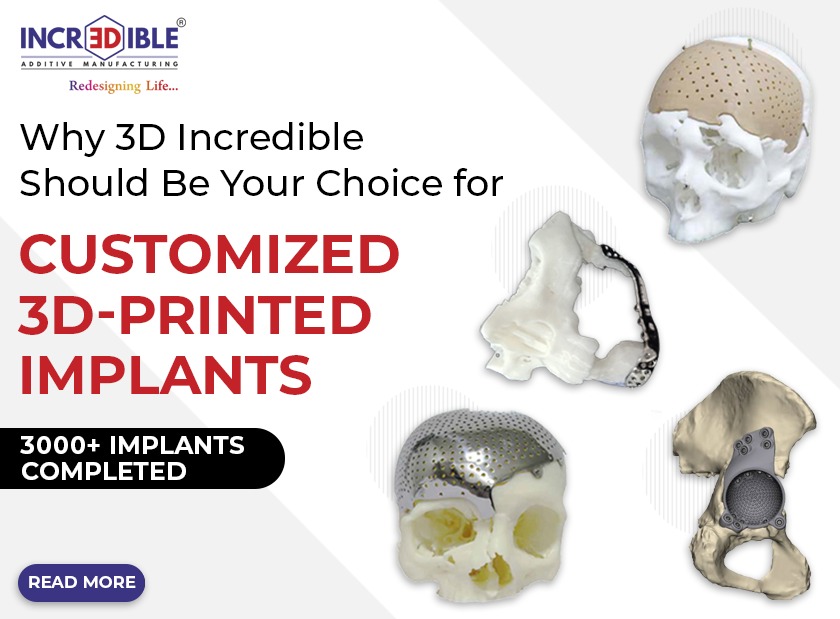

3D Incredible Pvt Ltd offers Patient-specific implants

Redefining precision in the implant industry, 3D Incredible Pvt. Ltd. is a shining example of innovation at work, utilizing 3D printing to its full potential. The company uses modern technologies, such as additive manufacturing and computer-aided design (CAD), to create implants that are customized for each patient.

These implants are tailored to the patients’ anatomies, enhancing their aesthetic appeal and increasing their functionality. Perfectly fitting implants minimize the need for significant surgical modifications, which is advantageous to surgeons. This precision in design and placement enhances surgical outcomes, reduces post-surgical complications, and contributes to improved patient satisfaction.

Conclusion

3D Incredible Pvt. Ltd. is a trailblazer in the ongoing debate between conventional and patient-specific implants, pushing the limits of what is possible with 3D printing technology. The selection of either of these two methods will depend on the particular requirements of every patient as the medical community continues to negotiate this revolutionary environment. The future of implant solutions seems to be one where precision is not only a standard but an expectation, redefining the possibilities for personalized healthcare, with 3D Incredible Pvt. Ltd. leading the charge.