Introduction:

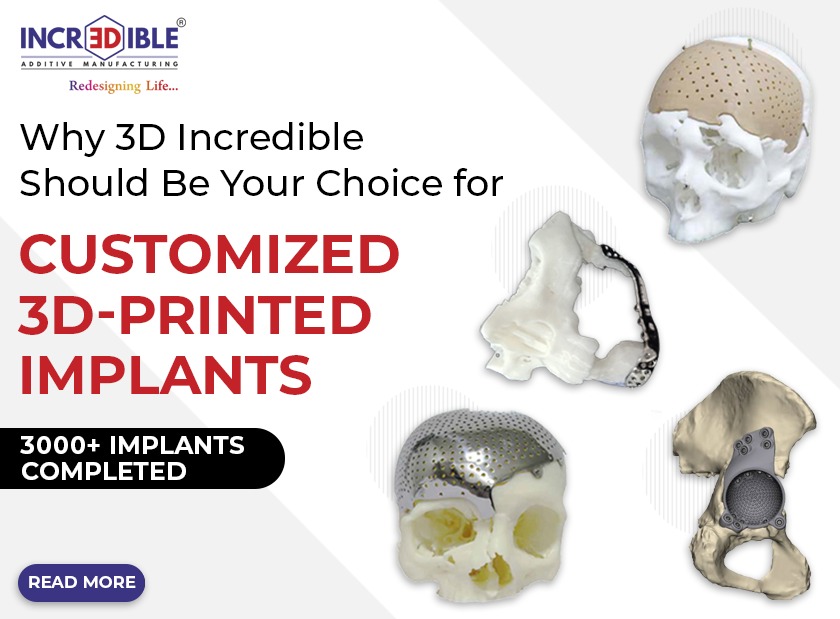

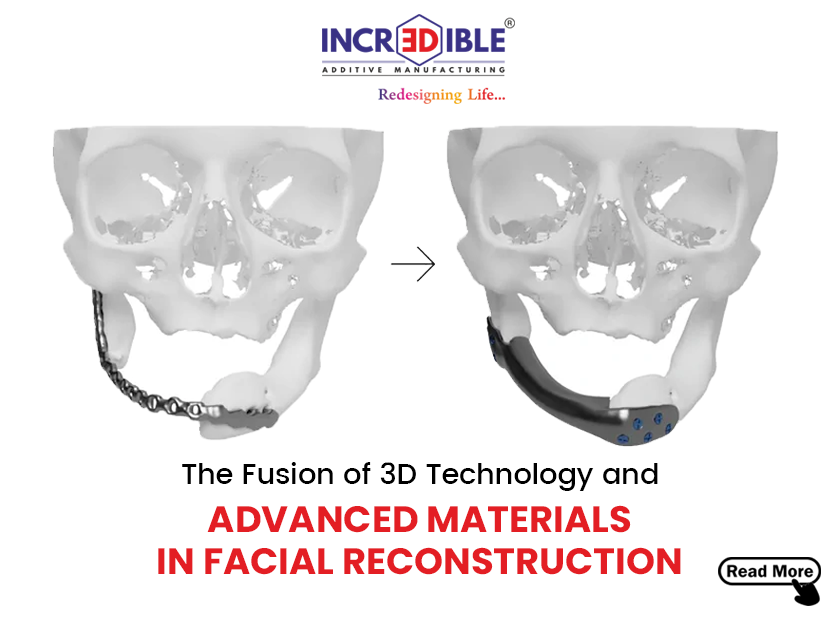

Incredible AM Pvt Ltd is India’s 1st & exclusive company in medical 3D Printing with a world-class facility certified by FDA norms. They hold ISO 13485 and ISO 9001 certifications, ensuring top-notch services. With a Class 10000 clean room, US-FDA-approved software, and an excellent team of medical experts, engineers, and consultants, Incredible AM delivers outstanding solutions like Customized Implants, Standard Implants, Bio models, and Cutting Guides.

Background:

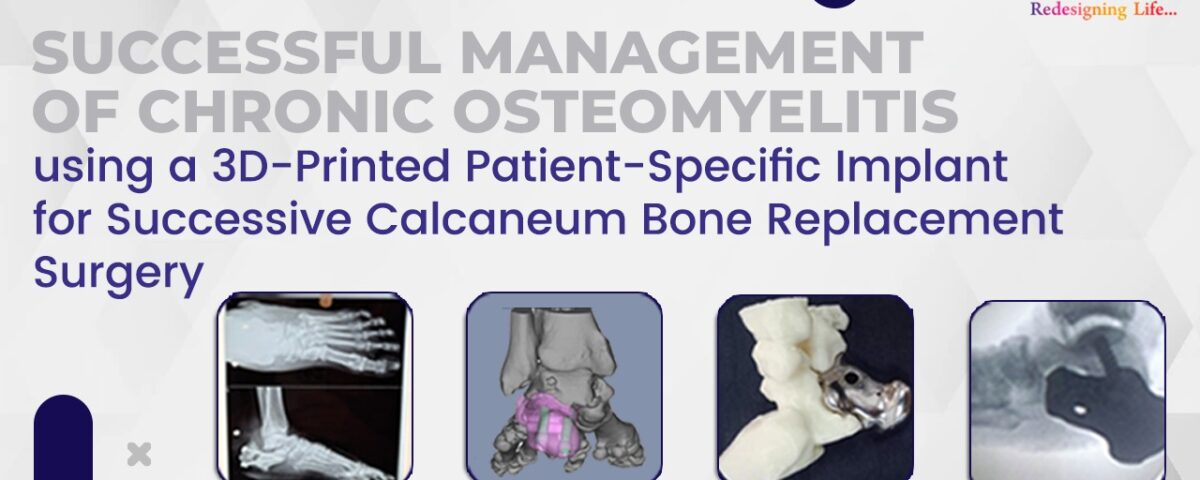

This case study presents a successful treatment of chronic osteomyelitis in a 55-year-old advocate, who previously underwent closed reduction & internal fixation for a one-year-old left calcaneum bone fracture. However, a subsequent infection led to chronic osteomyelitis. Conservative treatment for six months failed, necessitating alternative intervention.

Solution:

Dr. Girish Motwani, Central India’s first foot and ankle surgeon, adopted a two-stage treatment approach. Firstly, a total calcanectomy was performed to remove the osteomyelitis. To control any remaining infection, Vancomycin-coated bioabsorbable calcium phosphate granules were inserted. The patient was closely monitored for two months to ensure complete infection control and wound healing.

In the second stage, after confirming infection eradication and soft tissue healing, a 3D-printed custom-made calcaneal prosthetic implant, manufactured by 3D Incredible Medical Incredible, was prepared. The implant, made from Ti-6-Al-4-V-Eli, was designed to precisely fit the patient’s anatomy. It measured approximately 68mm in length and 35mm in breadth, with a mirror surface finish overall and a lattice structure in the bone contact region. The implant was secured to the talus using two 6.5mm cancellous screws. Additionally, the design incorporated three suture holes with a ½ circle profile and a length of 14mm for soft tissue engagement.

Post-implantation, the patient’s foot was immobilized for two months to facilitate healing and ensure implant stability.

Conclusion:

The 3D-printed implant was manufactured under ISO 13485 guidelines and underwent rigorous testing, ensuring an accurate fit and utmost safety. The customized Ti6Al4VELI implant effectively addressed chronic osteomyelitis, leading to successful infection control and functional recovery. This case underscores the significance of individualized surgical approaches, advanced techniques, and the expertise of specialized surgeons in achieving optimal results for complex foot pathologies.