The rapid advancement of 3D printing has resulted in the creation of a new learning and teaching tool for medical education. The ability to generate patient-specific in silico models from DICOM data obtained during CT, MRI, or ultrasound scanning has been combined with new, less expensive 3D printing technology. These printed models exhibit anatomical and structural fidelity consistent with the patient’s actual disease process, depending on the area of interest.

The right design and application of these models are determined by educational goals, as is the case with all teaching resources. There are essentially five crucial and frequently related steps in the 3D printing process that must be completed after the need has been determined in order to produce patient-specific models with anatomical and/or tissue fidelity. In this article, let us learn about these five ways in which 3d printing can enhance medical education.

- Understand the area of interest

Understanding the educational goal is the first step in developing a new 3D-printed educational tool for the medical field. Is it necessary to impart technical skills, preoperative planning, or anatomical knowledge? In addition, what area of the body needs to be included, and how much? In order to create the most educationally appropriate and cost-effective model, it is essential to understand the need you are attempting to address.

Four crucial aspects of the model should be taken into consideration when designing the 3D-printed version, and they should be in line with the demand for education. These are size, surrounding structures, surgical manipulation, and accuracy and resolution of the model. These factors will influence the type of imaging used to capture the area of interest, the required resolution, the kind of materials and composites used, and the type of 3D printer to be used. All of these will directly affect the production cost of a 3D-printed model.

Once the need has been established, a radiologist with the necessary expertise should be consulted to select the best medical imaging procedure for your particular 3D printed simulator as well as the accuracy of the imaging data for an accurate representation.

- Creating 3D geometry from an interest-area-specific dataset

After obtaining a sufficient clinical imaging dataset, a 3D geometric object must be made. Typically, one 3D object refers to one component that will be made of a single material. For instance, before joining them back together as an assembly before printing for proper fabrication, both geometries must be precisely defined separately if the assembly consists of two distinct objects, such as a bone and ligament. For clarity, the two items are frequently made of various materials or printed in various colours.

It is best to define various objects directly from the acquired DICOM image when they are present. To do this, extract points along the anatomical structure’s outline and specify its geometry. This process of extracting tissue structures into distinct objects is known as segmentation, which is frequently threshold-based. It is carried out using the colour contrast between tissue densities. Some people might prefer to divide a larger structure after defining the geometries; however, this can be a difficult task for those who are new to using design software.

- Converting the 3D object into a file ready for printing

The point clouds used to define the objects are exported into mesh-processing software in order to eliminate any visible artefacts that were selected points that weren’t necessary. Deformations can alter the structure’s original geometry by causing cavities or peaks. After the 3d model has been optimised, the object is described by a computational mesh made by connecting the cloud’s points into a grid.

The model’s interconnected components may at this point reveal new artefacts that need to be eliminated, as well as surface blemishes or jagged edges. The majority of irregularities can be corrected by simply using algorithms designed to remove details from the object to smooth its surfaces.

However, it should be remembered that excessive smoothing can deteriorate the 3D model’s resolution. In general, too little smoothing makes it necessary to define an object with more elements, whereas too much smoothing has the opposite effect. Controlling the number of elements is advised because doing computer manipulations becomes more challenging as the file size grows with the number of elements.

- Choosing the right 3D printer

It can be difficult to choose the best 3D printer to create a patient-specific model. Clarifying the model’s intended use and the educational needs before printing is extremely helpful. For instance:

Models made of hard materials are frequently sufficient to teach anatomy and explain pathology. If fine printing definition is not required, FDM, which is the least expensive and most accessible method, is unquestionably the best option. On the other hand, SLA models have more detail, making them better for small printing models such as 3d-printed models of coronary arteries.

Materials do not necessarily need to have the same mechanical properties as biological tissues for surgical planning and procedure review. Again, FDM and SLA may be your best options for a hard material model that accurately depicts the anatomical structure.

- Choosing the right material for obtaining a 3d model

Whether you want a 3d model with a rigid or flexible material or would like to use multiple materials, the 3D printing process, printer selection and the purpose for which the model is created. For instance:

Given that the majority of the materials used in 3D printing are rigid, human bones are the easiest biological tissues to replicate.

In the context of preprocedural planning, which has already demonstrated its capacity to enhance surgeons’ ability to think, interpret, and evaluate a procedure, as well as face a complex situation by simulating all steps in advance, rigid materials may also be suitable.

But most of the 3d printing materials fail to accurately mimic soft human biological tissue, so post-processing may be necessary to soften printed structures. However, with SLA, you can create flexible tissues and organs like hearts and cartilaginous trachea without the need for post-processing.

Conclusion

This blog post outlines how 3d-printed models are created to improve medical education.

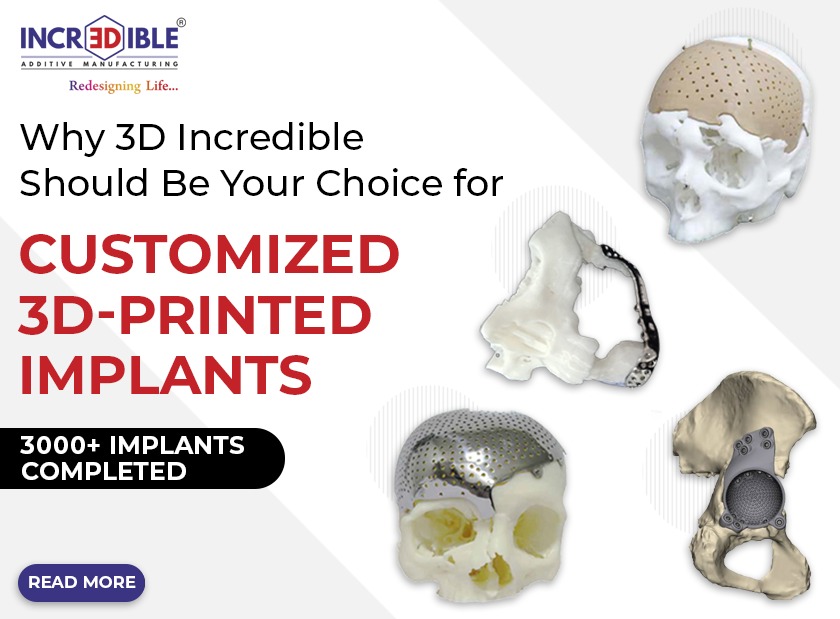

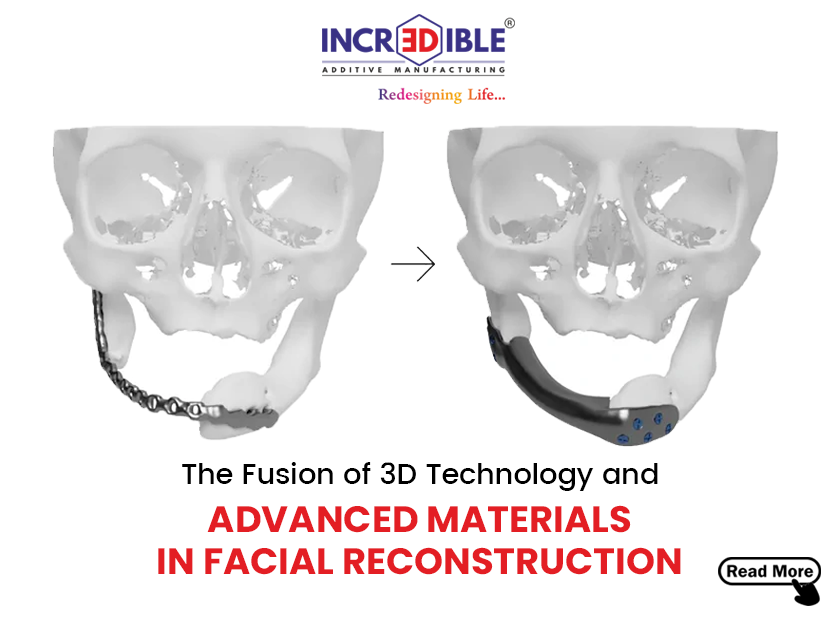

Incredible AM Pvt Ltd, a Pune-based additive manufacturing firm provides the best medical models as per the requirement. We make use of the latest technologies, such as FDM, SLA, and others creating such models. Additionally, our high-tech lab facility enables us to superimpose MRI and CT-scan data to recreate bony and soft tissues and organs mimicking the original and the most advanced 3d printer aids in getting the perfect model.

Visit Incredible AM Pvt Ltd to get perfect 3d-printed models for medical education.