Limbsal Ortho

Implant Specifications:

- Name of the surgeon : Dr. Girish Motwani

- Place : Suyog Hospital, Nagpur, MH

- Surface finish : Mirror surface overall and lattice structure in bone contact region

- Implant material : Ti-6-Al-4-V-Eli

- Implant Size & Weight : 68 x 35 mm, 143.952 gms

Introduction:

Incredible, India's first company to specialize in medical 3D printing, operates a world-class facility with ISO 13485 accreditation.

It built the facility under FDA requirements. It holds ISO 9001 and ISO 13485 certifications. Incredible's key characteristics include a class 10000 clean room, US-FDA-approved software, powerful technology, and a top-tier staff of doctors, engineers, biomedical engineers, CAD designers, and medical consultants.

It also does extensive validation and testing to validate the process and product, as well as deliver superior services to surgeons, hospitals, and patients. Incredible provides several medical 3D-printed products, including Cutting Guides, Customized Implants, and Bio Models.

Background :

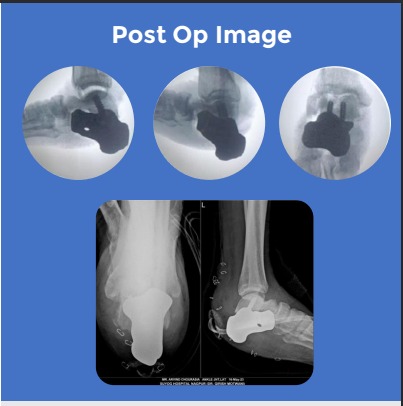

A 55-year-old advocate had successful treatment of chronic osteomyelitis through successive calcaneum bone replacement surgery at Suyog Hospital, Nagpur. The procedure was carried out by Dr Girish Motwani, Central India's first foot and ankle surgeon.

The instance demonstrates the effectiveness of a two-stage therapy procedure and the use of a 3D-printed patient-specific device to treat the difficult ailment.

Solution :

- The Patient’s Case Presentation

- Line of Treatment

The patient had undergone closed reduction and internal fixation for a one-year-old left calcaneum bone fracture. Regretfully, he had persistent osteomyelitis of the calcaneum as a result of an infection at the surgery site. The illness remained after six months of conservative treatment, requiring another course of action.

Dr. Girish Motwani used a two-phase therapeutic strategy. To eradicate the osteomyelitis, a complete calcanectomy was done in the initial phase. To manage any leftover infection, bioabsorbable calcium phosphate granules coated with vancomycin were used. For two months, the patient was under close observation to guarantee total wound healing and infection control.

In the second phase, a 3D-printed, specially-made calcaneal prosthetic implant was required. Dr Motwani discussed the case with the 3D Incredible team. After it was confirmed that the infection had been eradicated and the soft tissue had healed, the team developed the patient-specific implant.

The team used Ti-6-Al-4-V-Eli to create the implant, specifically engineered to match the anatomical structure of the patient. The implant was roughly 68 mm long and 35 mm wide, with a mirror-like surface finish and a lattice structure where it met the bone. Two 6.5mm cancellous screws were used to firmly anchor the implant to the talus. Three 1⁄2 circle suture holes with a 14mm length and profile were also included in the design for soft tissue engagement. For two months following implantation, the patient's foot was immobilized to promote healing and guarantee implant stability.

Quote from Doctor :

“Perfect 3D Printed implant for PS Type.”

Conclusion:

The implant was manufactured under ISO 13485 guidelines & tested to give an accurate fit & utmost safety. Once the resection was done, a customized implant from 3D Incredible was implanted.

Utilizing advanced technologies, such as 3D printing, has made it possible to create an implant that is specifically customized to fit the patient's anatomy. This example highlights how important customized surgical strategies, advanced methods, and the proficiency of skilled surgeons are to get the best outcomes possible for complicated foot diseases.

Incredible AM Pvt Ltd has put its plant, equipment, and procedures through extensive testing and validation to guarantee quality and safety.