Use of 3D printed customized implant for scapulareconstruction in totalscapulectomysurgery for treatment of Ewing’s Sarcoma

Implant Specifications:

- Name of the surgeon : Dr. Ravi Sauhta

- Place : Artemis Hospital, Haryana

- Surface finish : Matt finished

- Material : Patient specific anatomy model, patient specific scapula implant

Introduction:

Incredible AM Pvt. Ltd. is the first company in India working exclusively with Medical 3D printing in a certified world class facility. The company has built the facility as per FDA norms. It is certified with ISO 13485 and ISO 9001. Key features includes Class 10000 clean room, US-FDA approved software, state of the art equipment and also an excellent team of doctors, engineers, biomedical engineers, CAD designers and medical consultants who are there to deliver outstanding services to doctors, hospitals & patients with complete validation & tests conducted to certify the process & product. Incredible deals with Customized Implants, Standard Implants, Bio models as well as Cutting GuidesBackground :

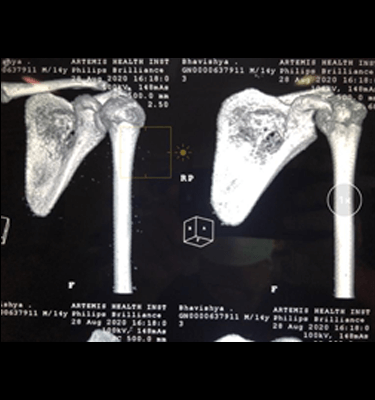

A male patient of 14-year-old hailing from Haryana, a student, complaint of mass on his left scapula region. Later-on histopathology report suggested Ewing’ssarcoma.Initially patient responded well to the chemo, but later on it was seen that tumor has grown with pain and discomfort. Dr.Ravi Sauhta, India’s Leading Orthopedic Surgeon in Artemis Hospital, Gurugram, Haryanadecided to go for tumor resection followed by reconstruction using customized implant for scapula, UHMWPE poly insert& Polypropylene mesh for capsule.

Lesion in left scapula

Solution :

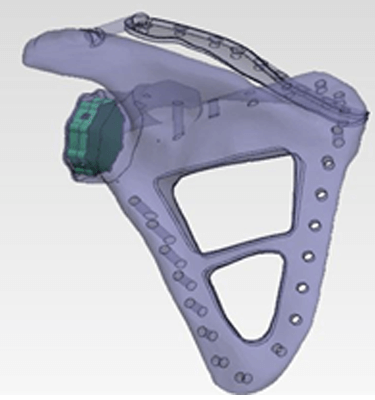

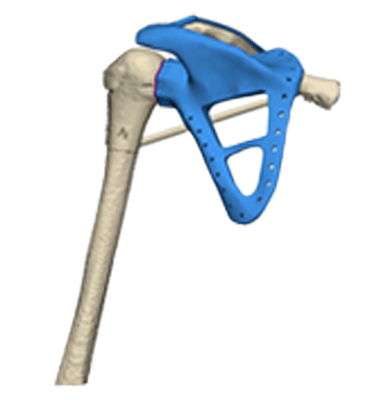

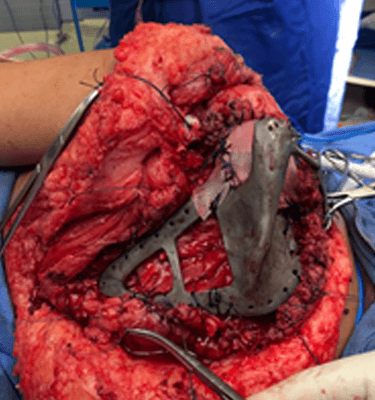

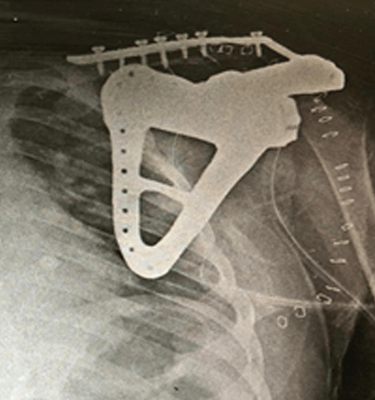

Dr. Ravi, India’s leading Orthopedic surgeon in Gurugram, Haryana decided to resect the tumor along with placement of 3D printed Implant.An encapsulated mass was found measuring 7 X 5 X 5 cm involving left Scapula and surrounding tissues, extending from base of acromion process to the scapular process. Incredible team discussed with Dr. Ravi, the designing and entire manufacturing process. It was initially started with surgical planning and case stimulation with the help of US FDA & CE approved Materialise Mimics software by superimposing CT & MRI DICOM data. Once the planning was finalized, the customized implant was designed along with UHMWPE poly liner matching the humerus head. The implant was designed in a way that the entire scapula is being replaced along with the polypropylene mesh replacing the capsule. The capsule was designed in way that it provides directional movements along with the ease of its attachment to implant and the bone.The design was completed with valuable inputs between the doctor and the Incredible design team together. The benefits of a 3D printed implant were its customization which resembled not only the particular anatomy required but also helped in better fixation. Finite Element Analysis was carried out which to determine the strength, stability and functionality of the implant.

Implant Designs

Cutting guide jigs

Cutting guide jigs

Quote from Doctor :

“Very satisfied with their personal approach and Quick Response.Since implant is of custom size it fit anatomically to the site of resection perfectly.”

Post-op images