Introduction to SLA 3D printing

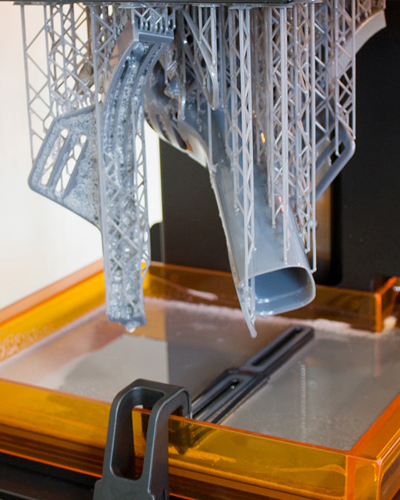

SLA (Stereolithography) 3D printing is an advanced technology that is transforming modern manufacturing.

It employs a photopolymerization process to form complex, high-resolution models with unparalleled accuracy. It begins with a computer model that is sliced into thin layers. The printing material is a vat of liquid resin. Layer by layer, the resin is selectively solidified by a laser beam that follows the CAD model. The building platform progressively rises as each layer hardens, enabling the subsequent layer to cure on top of the one before. Objects with intricate details and precise dimensions are created through a layer-by-layer process.

Advantages of SLA 3D Printing

Precision: SLA 3D printing provides unmatched precision, with the ability to create complex shapes and minute features with accuracy down to the micron.

Speed: SLA printing achieves remarkable print rates because it can cure whole resin layers in one shot.

Surface Quality: SLA prints have smooth surface finishes right out of the printer, which eliminates the need for finishing and post-processing.

Material Variety: A variety of photopolymer resins are compatible with SLA 3D printing, and each one has special qualities like flexibility, transparency, and biocompatibility.

Applications of SLA 3D Printing

SLA 3D printing finds applications in various industries. These include:

Product Development:

Rapid prototyping for functional testing and idea validation.

Jewelry and fashion:

Creating elaborate designs for jewelry and accessories for clothing.

Dental and Medical:

Producing prostheses, surgical guides, and dental models with remarkable precision.

Engineering:

Making molds, tooling parts, and intricate architectural models.

Education:

Adding visually appealing instructional models and prototypes to improve learning experiences.

Thus, SLA 3D printing is a game-changing technology that promotes innovation in various industries. It combines accuracy, speed, and adaptability and creates opportunities to translate concepts into reality with unparalleled precision and effectiveness.

Achievable Feature Size:

Pros & Cons

| Feature | SLA |

| Maximum Build Volume | 650x650x450mm |

| Wall thickness | 0.6-0.8mm |

| Holes | 0.8-1.0mm |

| Surface Finish | Better than Rest of the processes |

| Accuracy | 0.1 |

| Material | Clear (Rigid), Clear (Rigid), Castable (Blue) (Rigid), Flexible (Black)- |

| Mechanically | Strong and brittle, new flexible compounds available |

Pros

- Great value

- High accuracy

- Smooth surface finish

- Range of functional applications

Cons

- Sensitive to long exposure to UV light