- Benefits

- Application Industries

- process

- Case Study

What is it?

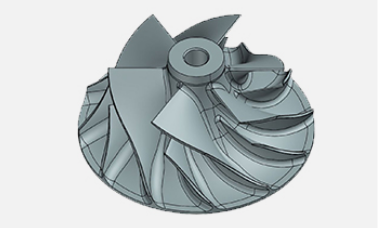

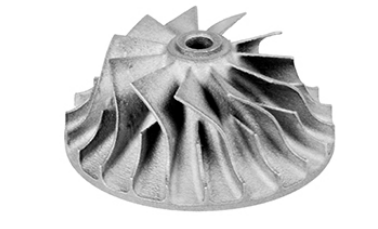

Advancement in laser technology has enabled us to scan a 3 dimensional part and convert it into the CAD file. In many industries, old machines are idle as a machine part had failed previously and the company couldn’t get the part from its original manufacturer. In such cases, the part can be scanned, and 3D printed which would switch ON the machine. The part even can be redesigned for better efficiency in operation. Lattice structure can be incorporated, or topology of the part can be optimised to reduce the weight of the part. In aerospace industry, Engine overhauling is a challenge where Engine parts need to be repaired or replaced. Mostly, aerospace components are designed and manufactured outside of India, and getting those parts from overseas may take a long time and a bulky cost. Those replacement parts can be Reverse Engineered, and 3D printed.

Benefits

- Produce obsolete parts

- Produce complex existing parts without having to design it in a CAD software

- Reduction in machine downtime

- Improve efficiency of existing parts

- Material and cost saving

Application Industries

Process