What is it?

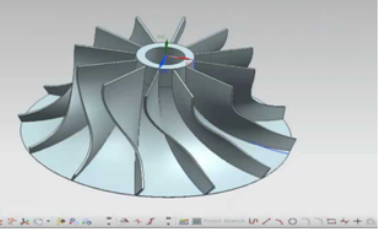

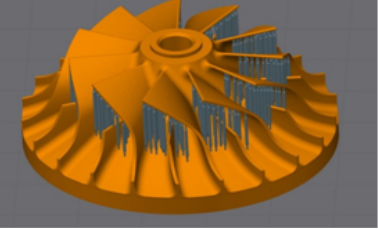

Product development is becoming competitive every day and companies are striving to launch their new products at the earliest, therefore companies are looking for effective options to design new products and manufacture them in a small quantity at shortest time possible. Rapid prototyping is almost a tool less process of manufacturing such small quantities. In this process, customers are required to come up with a CAD design which is an input to rapid prototyping machine. Software package slices the CAD model in thousands of small layers to produce it in the machine. The parts produced are functional and can be tested under severe conditions for validations. Most importantly, rapid prototyping process omits long supply chain, design and procurement of tools and need of costly equipment setup that consequently saves huge time, cost and efforts of product development process.

Benefits

- Significant reduction in part/assembly supply chain

- Reduction in product development cost by up to 60%

- Reduction in product development time by up to 80%

- Prototype & small Batch quantity

- Reduce design time/cost and development/procurement of tooling

Application Industries

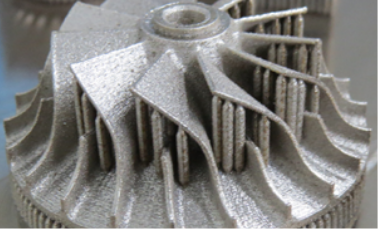

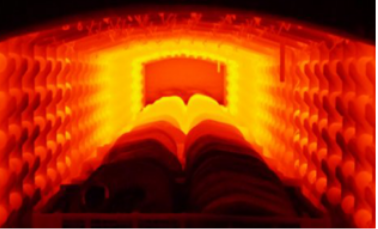

Process