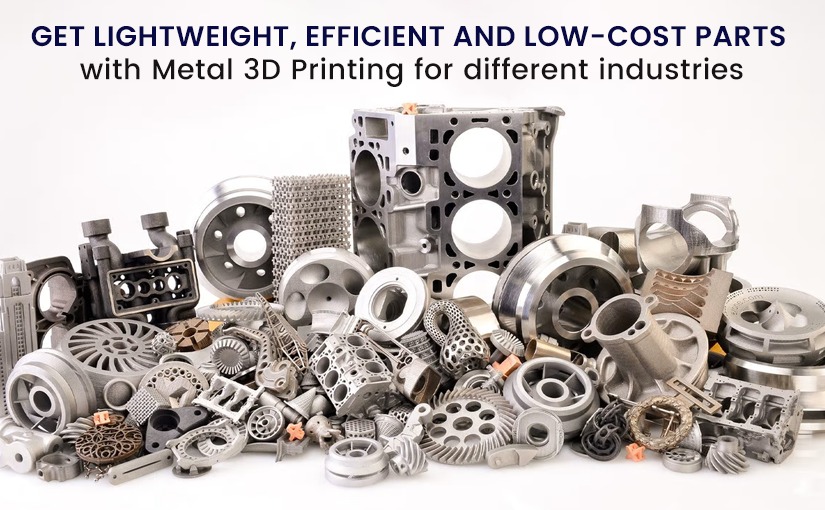

5 Key Benefits of 3D Metal Printing

In the last three decades, technological advancements have created new opportunities and lead to the discovery of several key inventions. Here are the some key benefits of 3d metal printing. In addition, the progress in technology has proved to be a stepping stone for multiple innovative technologies such as 3D metal printing. The 3D printing technology is a unique and cutting-edge technology owing to its ability to print three-dimensional objects that are highly beneficial to several industrial domains.

In the current scenario, 3D printing is gradually making its presence felt in several industries such as healthcare, automotive, engineering, and several other important industries. 3D Incredible has steadily transitioned into one of the leading players who offer the best 3D printing services. We have a team of some of the most highly skilled and experienced software developers and mechanical engineers who are dedicated and push themselves to go the extra mile.

As mentioned previously, 3D printing and with that 3D metal printing has gradually become an important aspect of several industrial domains. Let’s list down the various benefits of 3D metal printing and elaborate on the same.

1. Cost-effective

The traditional methods deployed for prototyping injection molds have proven to be expensive. However, with regards to metal additive manufacturing, 3D printing technology is an affordable and cost-efficient alternative to produce parts and tools compared to the traditional machining.

For example, in the healthcare domain, 3D printing of surgical tools is much more affordable than purchasing stainless steel tools and parts. Furthermore, the production of prosthetics with 3D printing technology is highly lucrative compared to the traditional techniques used over the years.

2. Reduces risks

3D printing a prototype significantly while working on a project. You can 3D print a prototype and test the same before investing hundreds of dollars in expensive molding tools. With this approach, it is easier to make changes to your design if required. Hence, 3D printing of prototypes before making substantial investments is beneficial and instills confidence as well.

3. Increases rate of production

The traditional process of manufacturing prototypes requires advanced tools and machinery. Apart from paying for the cost of labor and expensive equipment, the traditional process is relatively slow. The entire process could take several weeks to complete as your prototype would require several changes and alterations before it is finalized. From the business point of view, it is important to increase the production rate to avoid wastage of valuable time.

On the other hand, the 3D printing process takes a few hours only. After the initial design is complete, the design is then converted into a 3D prototype and the process is rapid and much more efficient. By replacing the traditional processes with 3D printing, the productivity increases exponentially.

4. Can be easily customized

In most industries, industrial players manufacture their products in bulk and all the products are designed using the same mold. Hence, all the products are similar in shape and have no room for modifications and alterations. However, the onset of 3D printing has proved to be an effective and efficient solution as it is easier to customize your prototype according to your needs without any added costs. As 3D printing can be easily customized, it has significantly gained popularity in several industries such as healthcare, automotive, etc.

5. Eco-friendly

In the current business and industrial landscape, it is important to take measures to protect the environment. In addition, industries are required to be responsible and work towards the sustainability of the environment. Compared to the conventional manufacturing processes, 3D printing is energy-efficient and produces a significantly lower quantity of waste. For example, airplane manufacturers discard around 90 percent of the material that is not of any use in the future. However, with the growth of metal additive manufacturing with 3D printing, less energy is required and the waste is reduced to a bare minimum. Hence, 3D metal printing is not only cheaper but also environmentally friendly.

3D printers and 3D metal printing have opened the doors for several businesses from multiple industrial domains such as healthcare, automotive, food industry, etc. Understanding the growing demand for 3D metal printing, we at 3D incredible are committed to offering the best metal 3D printing services. Research and development activities coupled with the growing demand for 3D printing, it is safe to say that the 3D printing industry will witness a significant amount of growth in the future.