3D Printing vs CNC Machining: 3D Printing have great future in Manufacturing

Comparison between 3d printing and CNC machine is elaborated very precisely just for understanding the advantages of 3d metal printing. Technological advancements along with constant research have pushed the growth of the 3D printing technology. In the current scenario, awareness regarding 3D printing technology and its potential has been realized by several industrial domains. In addition, 3D printing has gradually made an impact on the manufacturing sector and could replace traditional manufacturing techniques.

Although the concept of additive manufacturing and rapid prototyping has been around for a while, the capabilities of the 3D printers available at present have certainly changed the shape of manufacturing in recent years. Metal 3D printing has emerged as an excellent alternative to traditional printing due to the versatility, affordability, and accessibility if offers.

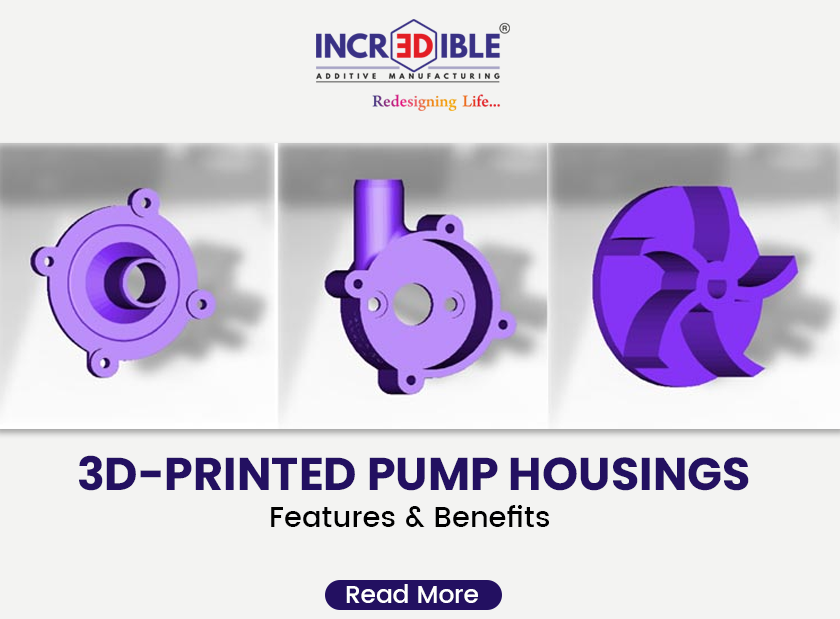

3D Incredible is at the forefront when it comes to the metal 3D printing services, metal 3D printing, and rapid prototyping services. We offer the most comprehensive and high-quality 3D printing services. In addition, we offer the best 3D printing solutions according to the requirements of our clients.

The advantages of 3D printing are endless. Let’s discuss the various benefits of 3D metal printing and its benefits in the manufacturing sector.

1. Ability to manufacture complex parts with 3D printing

Source: Shapeways

It is safe to say that manufacturing the complex mechanical parts or pieces has always been a challenge for traditional manufacturing as it demands immense skill and accuracy. In addition, even the slightest of errors could be disastrous for both, the manufacturer and the customer. Apart from the manufacturing process, even the assembly of these complex pieces is not an easy task.

However, the onset of 3D printing is a promising alternative as it has the ability to create these complex parts in a single process with the help of additive manufacturing. Furthermore, 3D printing effectively integrates the complexities of creating mechanical parts in the manufacturing process.

2. Single-step manufacturing

Source: Fabrisonic

For a designer, one of the biggest challenges is to design a product that involves a minimum number of manufacturing steps. In the case of traditional manufacturing, multiple steps are required to produce a majority of the parts. The multiple stages of a manufacturing process affect the manufacturability and the quality of the design.

However, the aforementioned issues are effectively solved by the 3D printing technology owing to its ability to manufacture an entire design in a single step. Once the CAD design is finalized, it is uploaded to the 3D printer and is printed in a single step within a couple of hours. Furthermore, the ability of 3D printers to manufacture a part in a single step largely reduces the dependence on the various manufacturing steps including, welding, painting, and machining

3. Products reach the market faster

Source: Siemens

We have already discussed how 3D printing is effective in solving several issues as far as prototyping is concerned. However, the benefits of 3D printing are not restricted to the financial aspect of the manufacturing process only but also the time parameter. The versatility of 3D printing ensures that the prototypes are developed faster and the entire process from the design part to production is rapid. Hence, 3D printing significantly increases the overall manufacturing output.

4. Waste reduction

3D printing technology plays a crucial role in reducing waste which is generated from raw materials in the case of traditional manufacturing. Hence, 3D printing increases the overall efficiency of raw materials. In 3D printing, the resource efficiency is optimum as only the material that is required is passed under a laser. However, in traditional marketing, the quantity of raw materials is much higher and hence, a lot of waste is generated. In a nutshell, 3D printing is not only cost-effective but also resource-efficient.

The potential of 3D printing for the manufacturing sector is promising. In addition, manufacturers have gradually started to implement 3D printing in their operations to increase productivity and return on investment. There is great potential for 3D printing in the manufacturing industry in the future. 3D Incredible is one of the most established organizations that offer metal 3D printing services and rapid prototyping services. In addition, we offer complete advanced 3D printing solutions based on the requirements of our clients.